Difference between revisions of "Multiphase Gas-Liquid Flow Behavior CFD Simulation in a T-junction Microchannel with Variation in Aspect Ratio and Cross-Sectional Shape with Constant Hydrodynamic Diameter"

Bintangf m (talk | contribs) (→Results and Discussion) |

Bintangf m (talk | contribs) (→Conclusion) |

||

| Line 118: | Line 118: | ||

==Conclusion== | ==Conclusion== | ||

| + | |||

| + | During the simulation, the effect of the hydraulic diameter is still not known due to the unavailability of a suitable model for a laminar multiphase micro-channel flow to capture the interfacial forces effect and the production of flow condition like slug flow, bubbly flow, etc. But, CFDSOF is able to simulate the flow behavior on a T-junction micro-channel correctly and gives satisfactory result. | ||

==Acknowledgement== | ==Acknowledgement== | ||

Revision as of 14:49, 5 January 2021

Authored by

Bintang Farhan Muhammad, Department of Mechanical Engineering, University of Indonesia

Contents

Abstract

N/A

Introduction

Multiphase flow provides an enhancement in performance parameters compared to single phase flow. Single phase flow has long diffusion time and Taylor dispersion and this problem can be reduced by adding a second immiscible fluid into the flow regime. This enhancement in mixing is measured by the reduction in the residence time distribution (RTD) due to the segmented flow that enhances mixing across phase boundaries and reduces dispersion. However, larger multiphase flow device usually cannot handle the flow parameters with high precision control. Thus, a new approach is required to deal with the pointed out limitation.

Micro-channels is one type of micro-structured device that flows two phase of fluids into a micro scale channel. Micro-structured device have a higher precision in the control of dispersion using high precision ability to control the generation of bubbles/droplets in the desired size. Heat and mass transfer coefficients are two to three orders of magnitude higher than the conventional counterparts. In micro-channels, many previous research has shown different flow behavior due to significant difference with an order-of-magnitude in the hydraulic diameter.

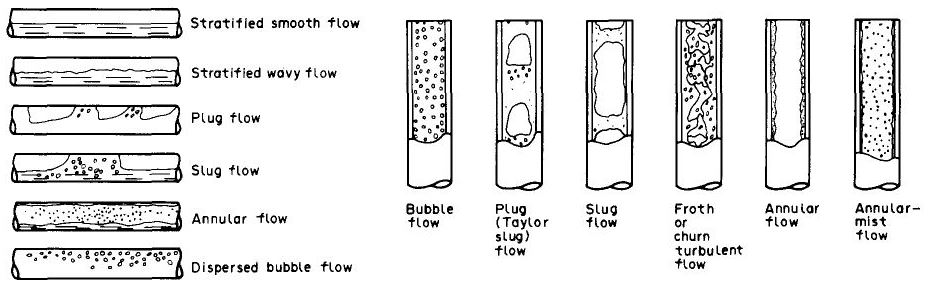

Although the flow should be laminar and well predicted due to low Reynolds number, the interfacial forces add complexity in micro-channel flow regime. Based on the review done by Gunther & Jensen (2006), flow patterns take several different forms, including channel spanning, slugs, suspended droplets, and wall wetting films, which depends on interaction among gravitational, interfacial, inertia, and viscous forces. Flow patterns in micro-channels is shown in figure 1 for horizontal and vertical micro-channels. This forces varies with operational condition and the geometry of the micro-channel itself. Kawahara et al. (2002) did an experimental research on gas-liquid micro-channel and found that there is a gradual shift in flow patterns with increasing gas and liquid flow rates. Based on the review of Sattari-Nafabajadi et al. (2018), will produce different mass transfer coefficient with different inlet angles, with variation in 60, 90,120,and 150 degrees, and the highest mass transfer coefficient was found to be at 90 degrees, which is a T-junction microchannel.

Although micro-fluidic flow research has been widely done, several topics has not yet been covered. Sattari-Nafabajadi et al. (2018) reviewed that researches on the effect of microchannel size are not sufficient to decide whether it is worthy enough to decrease the cross-sectional area to increase mixing performance in compromise of the pressure drop. Other than that, the aspect ratio, which regarded as the effective parameter on the manufacturing expenses, was not investigated in depth in the past research. Detailed assessment of influence of the channel cross section on dispersion also has not yet been established (Gunther & Jensen, 2006). Therefore, it is necessary to find the influence of aspect ratio and other geometrical parameters to the flow regime and characteristics.

With computational fluid dynamics (CFD) we are able to conduct research with flexible variation in geometry with low-cost. Previous micro-channel research has been done utilizing CFD as a means to study the flow behavior with variations in geometry (Aubin et al., 2009; Naher et al., 2011). This work aims to simulate using CFD to analyze the effect of geometrical parameters to its flow pattern and characteristics. In more detail, the research objectives are as follows:

1) To investigate the effect of variation on hydrodynamic diameter of circular micro-channel with constant aspect ratio to its flow patterns, pressure drop, axial dispersion, and RTD;

2) To investigate the effect of variation on aspect ratio in circular cross-section micro-channel to the flow pattern, pressure drop, axial dispersion, and RTD;

3) To give suggestion on the possible future experimental research based on the numerical simulation results;

The following chapters after this introduction will be structured as follows: 1) methodology, explains the fluid model and parameters, software and hardware utilized in this research, and computational method; 2) Results and discussion; and 3) Conclusion.

Methodology

This chapter outlines the methodology chosen for this work. The model assumption and verification will discuss the theory that will be the basis on model assumption, flow parameters, and boundary condition.

Software Description

Simulation is done on CFDSOF, a CFD software developed by CCIT Group. CFDSOF has been widely used, especially in Indonesia, by several universities and state-owned enterprises projects. Numerical fluid dynamics research has also been done using CFDSOF. The mesh generation and CFD simulation is conducted using CFDSOF. The result is then post-processed and presented using Paraview.

Model Assumption and Verification

Interfacial forces add complexities in micro-channel flow and thus will be considered in making model assumption. Review on the flow dynamics in micro-channel is presented in depth by Gunther and Jensen (2006). Generally, multiphase flow is also transient. Multiphase flow is characterized by three additional non-dimensional number, namely Bond number, capillary number, and Weber number.

Bond number is the ratio of interfacial forces to gravity. On microscale, interfacial forces often dominate over the influence of geometry. In channels narrower than 1mm interfacial forces begin to dominate and when it reaches 1µm they exceed six orders of magnitude. This is the case when the velocity of the flow is relatively low. On the other hand, if the flow exceeds several meters per second, inertial effect dominates over gravity and viscous forces, in which bubbles and droplets smaller than the hydraulic diameter can be formed and causes interfacial instabilities. Instabilities is caused in a rather complex manner. Based on the review of Gunther and Jensen, instability is categorized to three, namely capillary instability, pressure-drop induced breakup, and instabilities at higher flow rates, which will not be discussed in depth one by one. Different flow regime will also produced depending on the phase in the flow domain, whether it is gas-liquid or liquid-liquid multiphase flow. Mixing characteristics has also been measured in several research. In his review, Gunther and Jensen mentioned that dispersion in capillaries display a pronounced tailing effect in the RTD curve in which is caused by relatively short channel length, considering the high velocities, for the capillary measurements.

Based on the discussion above the following simulation model is constructed:

1) Bond number << 1 to ensure interfacial forces dominates the flow behavior, and thus neglecting the gravity.

2) Laminar flow model because the low Reynolds number given by small channel size low fluid flow velocities.

3) Transient flow to capture the instabilities.

4) Constant mass-flow rate.

5) Viscous flow to capture the effect of interfacial forces.

6) Calculation will not involve energy equation.

7) Air-water flow system will be used. Air and water density is assumed to be constant.

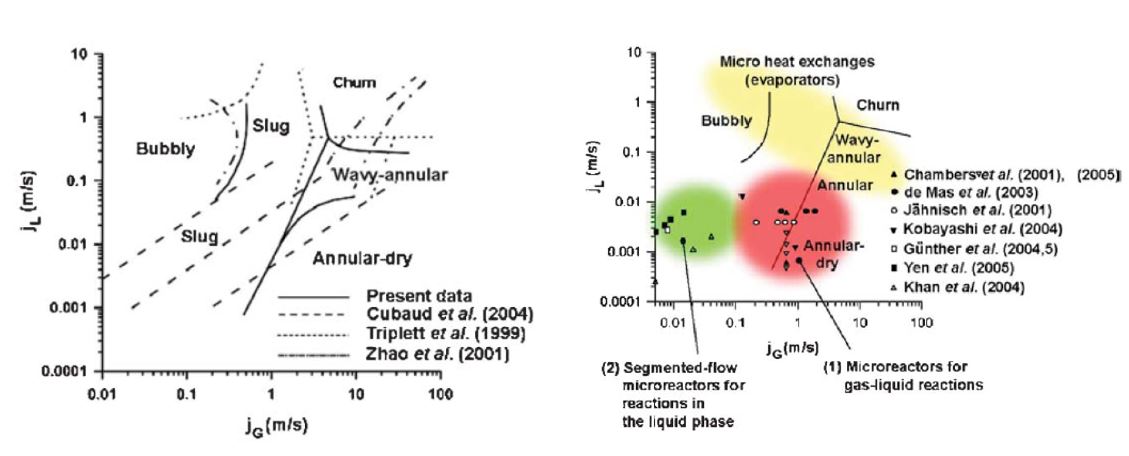

As an addition, the simulation will be conducted in a 2D model to reduce computation time and simulate more variation in geometry. The selected boundary conditions in each simulation will be based on Fig 2. which produces slug flow regime. JG and JL, the superficial gas and liquid velocity, respectively, will be selected at which produces Bo << 1. Details on the parameters are presented in Table 1.

| Parameters | Value |

|---|---|

| Gas superficial velocity (JG) (m/s) | 0.1 |

| Liquid superficial velocity (JL) (m/s) | 1.5 |

| ρair (kg/m3) | 1.201 |

| ρwater (kg/m3) | 998.2 |

| μwater (Pa.s) | 1E-3 |

Micro-channel Geometry

The geometries that are going to be simulated are T-junction microchannel with differentiation in 1) aspect ratio with constant hydrodynamic diameter with circular cross-section; and 2) hydrodynamic diameter in circular cross-section micro-channel with constant aspect ratio. The details of the geometrical parameters are shown in Table 2 and the dimensional notations are shown in Fig. 3.

| Config. Number | Dh (μm) | L (mm) | Aspect Ratio (AR) |

|---|---|---|---|

| Config. 1 | 500 | 50 | 1 |

| Config. 2 | 250 | 50 (66.667x40) | 0.59 |

| Config. 3 | 125 | 50 (80x30.36) | 0.3795 |

Parameters to be Analyzed

Gas-liquid micro-channel flow regime has been studies systematically and reviewed by Gunther and Jensen (2006), summarized in Fig. 2 which also shows the typical operating conditions. Most of the experiment were conducted in a air-water flow system. Past research has observed slip velocities, pressure profile, and other flow characteristics with respect to the corresponding non-dimensional quantities, such as Re, We, Ca, etc. In this work, the main parameters to be observed is the pressure drop and RTD, each will be analyzed with respect to the geometrical parameters. Commonly observed parameters, such as slip velocities, pressure profile, and flow regime, which will be observed qualitatively, will also be presented.

Results and Discussion

The results on meshing and flow simulation will be explained in this section. The drawbacks in this multiphase flow with CFDSOF will also be given in the subsequent sections.

Meshing and Testing

Meshing is done using CFDSOF meshing tools with geometry created using Autodesk Inventor 2019. The mesh can be seen on figure ... . The mesh size is the smallest possible mesh that can be achieved by CFDSOF, ensuring the most accurate result that can be achieved with CFDSOF. The test is then done using a single phase flow of water, with transient, incompressible, subsonic, turbulent (LES) flow. The result of the testing simulation shows satisfactory results in which the boundary layer is clearly captured. The pressure distribution in the flow regime also shows satisfactory results. Therefore the mesh is adequate enough to be simulated on the multiphase flow of water-air system.

Drawbacks in Multiphase Flow of Water-Air System Simulation

As we proceed to the multiphase flow, there is several drawbacks while doing the simulation. While most micro-channel flow uses Eulerian-Eulerian or VOF, CFDSOF solver for both of this model is currently unavailable. Therefore, the only flow simulation that can be used is the Eulerian-Lagrangian flow model, where the dispersed phase is either treated as a droplet or particles, thus it is unable to capture the slug flow behavior. This is due to the fact that flow behavior in multiphase micro-channel flow is strongly affected by the interfacial effect of both phase and by making it to be a droplet/particle it cannot capture the interfacial forces. After selecting the Eulerian-Lagrangian flow model, CFDSOF model for laminar flow and neglected-gravity flow (Bo << 1) is currently unavailable, while on the other hand, most of the research regarding micro-channel flow is in laminar flow due to its small diameter and low flow velocity. Therefore, we need to select turbulent flow and cannot neglect the gravity in this simulation.

We then proceed to set the boundary condition of the inlet, outlet, wall, and discrete particles. The inlet is set to be a velocity inlet boundary condition with variation as shown in table 1. Outlet boundary condition is set to be pressure outlet with 0 m2/s2. Wall is set to be in no slip condition. Then, the discrete phase is set to be air with properties as shown in table 2, with boundary injection at the top inlet with velocity matching the velocity inlet, fixed particle size distribution, and sphere drag model. Injected mass is set to be 0.5kg and is injected for 40 seconds, matching the simulation time, with 50000 as the number of parcels. We then proceed for trial and error and testing whether the parameter and the boundary condition can result in converged simulation.

After testing for two weeks, none of the multiphase flow simulation resulted in a loosely converged, or better, result. All of the simulation did not converged and automatically terminated because the residuals is almost near unity. Changing the fluid flow model to RANS resulted in the same result. Changing the boundary condition to a turbulent flow by increasing the velocity also did not make the simulation converge. The residuals achieved during the single phase flow is satisfactory, reaching 1E-6, while on the other hand, the simulation on the multiphase flow never goes below 0.5. I tried to troubleshoot this problem for two weeks straight but due to this problem I wasn't able to simulate other geometry of the micro-channel.

Conclusion

During the simulation, the effect of the hydraulic diameter is still not known due to the unavailability of a suitable model for a laminar multiphase micro-channel flow to capture the interfacial forces effect and the production of flow condition like slug flow, bubbly flow, etc. But, CFDSOF is able to simulate the flow behavior on a T-junction micro-channel correctly and gives satisfactory result.

Acknowledgement

This research was conducted to complete the computational fluid dynamics class, in Mechanical Engineering Department, Universitas Indonesia, as the final project. The author thank Dr. Ahmad Indra as our advisor, and also Bang Edo, Bang Bani, Ales, Abi, Elvin, Mas Agus, Josiah, and all other students for the valuable discussion in creating this research paper.

References

Aubin, J., Prat, L., Xuereb, C. and Gourdon, C., 2009. Effect of microchannel aspect ratio on residence time distributions and the axial dispersion coefficient. Chemical Engineering and Processing: Process Intensification, 48(1), pp.554-559.

Günther, A. and Jensen, K., 2006. Multiphase microfluidics: from flow characteristics to chemical and materials synthesis. Lab Chip, 6(12), pp.1487-1503.

Kawahara, A., Chung, P. and Kawaji, M., 2002. Investigation of two-phase flow pattern, void fraction and pressure drop in a microchannel. International Journal of Multiphase Flow, 28(9), pp.1411-1435.

Kawaji, M., Mori, K. and Bolintineanu, D., 2009. The Effects of Inlet Geometry and Gas-Liquid Mixing on Two-Phase Flow in Microchannels. Journal of Fluids Engineering, 131(4).

Moreau, M., Di Miceli Raimondi, N., Le Sauze, N., Gourdon, C. and Cabassud, M., 2017. A new numerical method for axial dispersion characterization in microreactors. Chemical Engineering Science, 168, pp.178-188.

Naher, S., Orpen, D., Brabazon, D., Poulsen, C. and Morshed, M., 2011. Effect of micro-channel geometry on fluid flow and mixing. Simulation Modelling Practice and Theory, 19(4), pp.1088-1095.

Sattari-Najafabadi, M., Nasr Esfahany, M., Wu, Z. and Sunden, B., 2018. Mass transfer between phases in microchannels: A review. Chemical Engineering and Processing - Process Intensification, 127, pp.213-237.