Difference between revisions of "Muhammad Ammar Anuttara"

Ammaranttr (talk | contribs) (→Introduction) |

Ammaranttr (talk | contribs) (→Hydrogen Tank Summary) |

||

| (29 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Introduction == | == Introduction == | ||

| − | [[File: Muhammad_Ammar_Anuttara.jpg| | + | [[File: Muhammad_Ammar_Anuttara.jpg|250x250px|Photo of myself|thumb|middle]] |

| − | I’m a Mechanical Engineering student at Universitas Indonesia who is also a creative worker with adept social skills that is willing to work as a team. I’m able to adapt to most conditions and not afraid to learn something new. | + | My name is '''Muhammad Ammar Anuttara''', but people usually call me '''Ammar'''. I’m a Mechanical Engineering student at Universitas Indonesia who is also a creative worker with adept social skills that is willing to work as a team. I’m able to adapt to most conditions and not afraid to learn something new. |

| + | |||

| + | You can contact me through my LinkedIn[https://www.linkedin.com/in/ammar-anuttara-239701202]. | ||

| + | == Optimization of a Hydrogen Tank == | ||

| + | |||

| + | Today, we will discuss the optimization of a '''1 litre, 8 bar''' pressured hydrogen storage tank. We will optimise its price-to-performance ratio to be as effective as it can be budget-friendly. | ||

| + | |||

| + | Before we proceed, we need to know the components of a standard hydrogen tank. A hydrogen tank consists of these items: | ||

| + | |||

| + | [[File: Hydrogen_Tank_in_Details_2.png|thumb|left|Components of a hydrogen tank.]] | ||

| + | |||

| + | #Base Tank (usually made out of steel and lined with other materials for thermal insulation) | ||

| + | #Neck | ||

| + | #Outer Wrapping | ||

| + | #Valves | ||

| + | #End Plug | ||

| + | #Pressure Gauge | ||

| + | #Pressure Relief Device | ||

| + | #Mounting brackets | ||

| + | |||

| + | To optimise the price-to-performance ratio, we can consider these components and materials for our hydrogen tank. | ||

| + | |||

| + | *First, we are going to use an aluminium alloy tank. Aluminium alloy is generally a great cost-effective material used in hydrogen tanks. They have sufficient strength and durability while having a relatively low cost. A great alternative to aluminium alloy would be steel as it offers more or less the same benefits and cost. These materials will also be used for the mounting brackets | ||

| + | |||

| + | *Since our hydrogen tank is low-pressure, the perfect material for thermal insulation is polyurethane foam. Polyurethane foam insulation is cost-effective and widely used for low-pressure applications. It provides good thermal insulation properties, reducing heat transfer and keeping the hydrogen at a stable temperature. | ||

| + | |||

| + | *The pressure relief device of our hydrogen tank would be a spring-loaded valve. Using this option would be as cost-effective as it could be because this variant does not use any electronics and does the job well to release excess pressure. For the pressure gauge, we will be using a bourdon tube pressure gauge. | ||

| + | |||

| + | *Lastly, our valves will be using brass or stainless steel. Valves made from brass or stainless steel can be affordable and suitable for low-pressure applications. These materials provide good corrosion resistance and can withstand the operating pressure of 8 bars. | ||

| + | |||

| + | == Hydrogen Tank Design == | ||

| + | |||

| + | Considering the optimization of the hydrogen tank that we are trying to build, we need to know the dimensions and properties of the hydrogen tank we are using. These are the known variables of the hydrogen tank we are designing: | ||

| + | |||

| + | *Yield strength (alluminium alloy) = '''300 MPa''' | ||

| + | *Volume = '''1 litre''' or '''0.001 cubic metres''' | ||

| + | *Pressure (P) = '''8 bars''' or '''0.8 MPa''' | ||

| + | *Height (H) = '''50 cm''' or '''0,5 m''' | ||

| + | |||

| + | To calculate the required thickness for the aluminum alloy pressure vessel, we need to consider the hoop stress equation and apply the safety factor. | ||

| + | |||

| + | The hoop stress equation for a cylindrical pressure vessel is given by: | ||

| + | |||

| + | σ_hoop = P * D / (2 * t) | ||

| + | |||

| + | Where: | ||

| + | σ_hoop is the hoop stress | ||

| + | P is the internal pressure | ||

| + | D is the diameter of the vessel | ||

| + | t is the thickness of the vessel | ||

| + | |||

| + | The required thickness can be calculated as: | ||

| + | |||

| + | t = P * D / (2 * σ_hoop * SF) | ||

| + | |||

| + | Where: | ||

| + | SF is the safety factor (5) | ||

| + | |||

| + | Let's calculate the required thickness using the provided values (using Python as our programming language): | ||

| + | |||

| + | import math | ||

| + | |||

| + | # Given values | ||

| + | yield_strength = 300 # MPa | ||

| + | volume = 1 # liter | ||

| + | pressure = 8 # bars | ||

| + | height = 0.5 # meters | ||

| + | safety_factor = 5 | ||

| + | joint_efficiency = 0.80 | ||

| + | |||

| + | # Convert pressure from bars to MPa | ||

| + | pressure_mpa = pressure * 0.1 | ||

| + | |||

| + | # Calculate the internal diameter of the vessel | ||

| + | radius = math.sqrt((volume * 1000) / (math.pi * height)) | ||

| + | diameter = 2 * radius | ||

| + | |||

| + | # Calculate the allowable stress | ||

| + | allowable_stress = yield_strength / safety_factor | ||

| + | |||

| + | # Calculate the hoop stress | ||

| + | hoop_stress = pressure_mpa * diameter / 2 | ||

| + | |||

| + | # Calculate the required thickness | ||

| + | thickness = pressure_mpa * diameter / (2 * hoop_stress * joint_efficiency) | ||

| + | |||

| + | print(f"The required thickness is: {thickness} mm") | ||

| + | |||

| + | With this calculation, we can achieve the number of the thickness to be '''1.25 mm'''. | ||

| + | |||

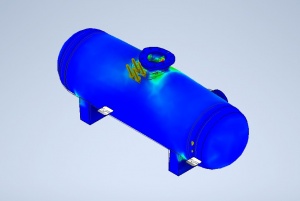

| + | We now have the necessary variables for our hydrogen tank, so we can design the hydrogen tank using Inventor, a 3D CAD application. This is the result of the model and the stress analysis. | ||

| + | |||

| + | [[File: Tank_Ammar.jpg|thumb|center|Hydrogen tank design in inventor.]] | ||

| + | |||

| + | [[File: Stress_Analysis_Tank_Ammar.jpg|thumb|center|Stress analysis of said hydrogen tank.]] | ||

| + | |||

| + | == Material and Price Analysis == | ||

| + | |||

| + | To calculate the material required for the hydrogen tank, we need to determine the surface area of the tank and multiply it by the thickness. Assuming the tank is cylindrical in shape with a butt joint weld, we can calculate the material volume using the following code. | ||

| + | |||

| + | import math | ||

| + | |||

| + | # Given values | ||

| + | volume = 1 # liter | ||

| + | height = 0.5 # meters | ||

| + | joint_efficiency = 0.80 | ||

| + | thickness = 1.2 / 1000 # Convert thickness from mm to meters | ||

| + | |||

| + | # Calculate the internal diameter of the tank | ||

| + | radius = math.sqrt(volume / (math.pi * height)) | ||

| + | diameter = 2 * radius | ||

| + | |||

| + | # Calculate the surface area of the tank | ||

| + | A_cylinder = math.pi * diameter * height | ||

| + | A_ends = 2 * (math.pi * (diameter / 2) ** 2) | ||

| + | A_total = A_cylinder + A_ends | ||

| + | |||

| + | # Calculate the material area | ||

| + | material_area = A_total * thickness | ||

| + | |||

| + | print(f"The material area required is: {material_area} square meters") | ||

| + | |||

| + | Using this code, we get a material area of 80 square centimeters | ||

| + | |||

| + | So now, we know that we need 80 square centimeters of alluminium alloy to make this tank. 80 square centimeters of alluminium alloy cost around '''Rp60.000'''[https://www.tokopedia.com/soember-suksess/plat-alumunium-2-mm-x-40-mm-x-90-mm?extParam=ivf%3Dfalse&src=topads] | ||

| + | The Polyurethane for the lining inside will cost around '''Rp75.000'''[https://www.tokopedia.com/dsalamstore/polyurethane-foam-pu-foam-foam-sealant-750ml-bonus-paranet?extParam=ivf%3Dtrue&src=topads] | ||

| + | For the valve, a standard spring loaded one cost about '''Rp115.000'''[https://www.tokopedia.com/safetysupplier/3-4-spring-loaded-brass-check-valve-showy-5102?utm_source=google&utm_medium=organic&utm_campaign=pdp-seo] | ||

| + | Lastly, for supports and other needs, we would buy a few steel rods at around '''Rp50.000'''[https://www.tokopedia.com/sinarsuksesabadi/8-mm-as-shaft-rod-stainless-steel-sus-201?extParam=ivf%3Dfalse&src=topads] | ||

| + | |||

| + | This brings our grand total to about '''Rp300.000''' | ||

| + | |||

| + | == Hydrogen Tank Summary == | ||

| + | In conclusion, the hydrogen tank that we designed will be an effictive tool to store low pressure hydrogen in a budget friendly way. Below is a link to my video on the hydrogen tank. | ||

| + | |||

| + | Link to my video https://www.youtube.com/watch?v=psS0RjGUK_s | ||

Latest revision as of 23:58, 11 June 2023

Contents

Introduction

My name is Muhammad Ammar Anuttara, but people usually call me Ammar. I’m a Mechanical Engineering student at Universitas Indonesia who is also a creative worker with adept social skills that is willing to work as a team. I’m able to adapt to most conditions and not afraid to learn something new.

You can contact me through my LinkedIn[1].

Optimization of a Hydrogen Tank

Today, we will discuss the optimization of a 1 litre, 8 bar pressured hydrogen storage tank. We will optimise its price-to-performance ratio to be as effective as it can be budget-friendly.

Before we proceed, we need to know the components of a standard hydrogen tank. A hydrogen tank consists of these items:

- Base Tank (usually made out of steel and lined with other materials for thermal insulation)

- Neck

- Outer Wrapping

- Valves

- End Plug

- Pressure Gauge

- Pressure Relief Device

- Mounting brackets

To optimise the price-to-performance ratio, we can consider these components and materials for our hydrogen tank.

- First, we are going to use an aluminium alloy tank. Aluminium alloy is generally a great cost-effective material used in hydrogen tanks. They have sufficient strength and durability while having a relatively low cost. A great alternative to aluminium alloy would be steel as it offers more or less the same benefits and cost. These materials will also be used for the mounting brackets

- Since our hydrogen tank is low-pressure, the perfect material for thermal insulation is polyurethane foam. Polyurethane foam insulation is cost-effective and widely used for low-pressure applications. It provides good thermal insulation properties, reducing heat transfer and keeping the hydrogen at a stable temperature.

- The pressure relief device of our hydrogen tank would be a spring-loaded valve. Using this option would be as cost-effective as it could be because this variant does not use any electronics and does the job well to release excess pressure. For the pressure gauge, we will be using a bourdon tube pressure gauge.

- Lastly, our valves will be using brass or stainless steel. Valves made from brass or stainless steel can be affordable and suitable for low-pressure applications. These materials provide good corrosion resistance and can withstand the operating pressure of 8 bars.

Hydrogen Tank Design

Considering the optimization of the hydrogen tank that we are trying to build, we need to know the dimensions and properties of the hydrogen tank we are using. These are the known variables of the hydrogen tank we are designing:

- Yield strength (alluminium alloy) = 300 MPa

- Volume = 1 litre or 0.001 cubic metres

- Pressure (P) = 8 bars or 0.8 MPa

- Height (H) = 50 cm or 0,5 m

To calculate the required thickness for the aluminum alloy pressure vessel, we need to consider the hoop stress equation and apply the safety factor.

The hoop stress equation for a cylindrical pressure vessel is given by:

σ_hoop = P * D / (2 * t)

Where: σ_hoop is the hoop stress P is the internal pressure D is the diameter of the vessel t is the thickness of the vessel

The required thickness can be calculated as:

t = P * D / (2 * σ_hoop * SF)

Where: SF is the safety factor (5)

Let's calculate the required thickness using the provided values (using Python as our programming language):

import math

# Given values yield_strength = 300 # MPa volume = 1 # liter pressure = 8 # bars height = 0.5 # meters safety_factor = 5 joint_efficiency = 0.80

# Convert pressure from bars to MPa pressure_mpa = pressure * 0.1

# Calculate the internal diameter of the vessel radius = math.sqrt((volume * 1000) / (math.pi * height)) diameter = 2 * radius

# Calculate the allowable stress allowable_stress = yield_strength / safety_factor

# Calculate the hoop stress hoop_stress = pressure_mpa * diameter / 2

# Calculate the required thickness thickness = pressure_mpa * diameter / (2 * hoop_stress * joint_efficiency)

print(f"The required thickness is: {thickness} mm")

With this calculation, we can achieve the number of the thickness to be 1.25 mm.

We now have the necessary variables for our hydrogen tank, so we can design the hydrogen tank using Inventor, a 3D CAD application. This is the result of the model and the stress analysis.

Material and Price Analysis

To calculate the material required for the hydrogen tank, we need to determine the surface area of the tank and multiply it by the thickness. Assuming the tank is cylindrical in shape with a butt joint weld, we can calculate the material volume using the following code.

import math

# Given values volume = 1 # liter height = 0.5 # meters joint_efficiency = 0.80 thickness = 1.2 / 1000 # Convert thickness from mm to meters

# Calculate the internal diameter of the tank radius = math.sqrt(volume / (math.pi * height)) diameter = 2 * radius

# Calculate the surface area of the tank A_cylinder = math.pi * diameter * height A_ends = 2 * (math.pi * (diameter / 2) ** 2) A_total = A_cylinder + A_ends

# Calculate the material area material_area = A_total * thickness

print(f"The material area required is: {material_area} square meters")

Using this code, we get a material area of 80 square centimeters

So now, we know that we need 80 square centimeters of alluminium alloy to make this tank. 80 square centimeters of alluminium alloy cost around Rp60.000[2] The Polyurethane for the lining inside will cost around Rp75.000[3] For the valve, a standard spring loaded one cost about Rp115.000[4] Lastly, for supports and other needs, we would buy a few steel rods at around Rp50.000[5]

This brings our grand total to about Rp300.000

Hydrogen Tank Summary

In conclusion, the hydrogen tank that we designed will be an effictive tool to store low pressure hydrogen in a budget friendly way. Below is a link to my video on the hydrogen tank.

Link to my video https://www.youtube.com/watch?v=psS0RjGUK_s