Difference between revisions of "User:Kevin.andriano"

(→FINAL PROJECT EXPERIMENT RESULT) |

|||

| (28 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | |||

| + | == INTRODUCTION == | ||

| + | [[File:G20.jpg|200px]] | ||

| + | |||

| + | Name : Kevin Andriano Sularto | ||

| + | |||

| + | NPM : 1906316181 | ||

== RELATIONSHIP BETWEEN SUGAR CANE COMPANY, AUTOMOTIVE COMPANY, AND OIL AND GAS COMPANY == | == RELATIONSHIP BETWEEN SUGAR CANE COMPANY, AUTOMOTIVE COMPANY, AND OIL AND GAS COMPANY == | ||

There may be several ways to think about the relationship between a sugar cane factory, an automotive factory, and an oil and gas company, but here are a few possible perspectives: | There may be several ways to think about the relationship between a sugar cane factory, an automotive factory, and an oil and gas company, but here are a few possible perspectives: | ||

| − | + | [[File:Sugar_Industry-1.jpg]] | |

'''Supply chain:''' Sugar cane, oil, and gas are all used as inputs in various industries, including automotive manufacturing. A sugar cane factory produces sugar, which can be used to make ethanol, a biofuel that can be blended with gasoline. Oil and gas companies produce the gasoline and other petroleum-based products that are used to power vehicles. An automotive factory uses both biofuels and petroleum-based fuels to power the cars it produces. Therefore, there is a supply chain relationship between these industries. | '''Supply chain:''' Sugar cane, oil, and gas are all used as inputs in various industries, including automotive manufacturing. A sugar cane factory produces sugar, which can be used to make ethanol, a biofuel that can be blended with gasoline. Oil and gas companies produce the gasoline and other petroleum-based products that are used to power vehicles. An automotive factory uses both biofuels and petroleum-based fuels to power the cars it produces. Therefore, there is a supply chain relationship between these industries. | ||

| Line 11: | Line 18: | ||

Overall, the relationship between a sugar cane factory, an automotive factory, and an oil and gas company is complex and multifaceted, and can be examined from various angles. | Overall, the relationship between a sugar cane factory, an automotive factory, and an oil and gas company is complex and multifaceted, and can be examined from various angles. | ||

| + | |||

| + | |||

| + | == INDIVIDUAL PROJECT == | ||

| + | |||

| + | HYBRID DIESEL VEHICLE / HYBRID GASOLINE VEHICLE / ELECTRIC VEHICLE. WHICH ONE IS BETTER? | ||

| + | |||

| + | A hybrid diesel vehicle is a type of hybrid vehicle that uses a combination of a diesel engine and an electric motor to power the vehicle. In this type of vehicle, the diesel engine works in tandem with an electric motor and battery to provide propulsion and improve fuel efficiency. | ||

| + | |||

| + | The electric motor in a hybrid diesel vehicle can be used in different ways, depending on the design of the vehicle. For example, in some hybrid diesel vehicles, the electric motor is used to assist the diesel engine during acceleration, providing additional power to the wheels and reducing the load on the diesel engine. This can help to improve fuel efficiency and reduce emissions. | ||

| + | |||

| + | In other hybrid diesel vehicles, the electric motor can be used to power the vehicle on its own at low speeds, such as in stop-and-go traffic, while the diesel engine takes over at higher speeds or when more power is needed. This can help to improve fuel efficiency in city driving conditions, where the vehicle spends a lot of time idling and accelerating slowly. | ||

| + | |||

| + | Hybrid diesel vehicles can provide a number of benefits, including improved fuel efficiency, reduced emissions, and increased performance. They are often used in commercial and industrial applications, such as buses and delivery trucks, where fuel efficiency and environmental impact are important factors. However, they can also be used in passenger cars and SUVs, providing a greener and more efficient alternative to traditional gasoline or diesel engines. | ||

| + | |||

| + | |||

| + | == VIDEO SYNOPSIS == | ||

| + | |||

| + | https://youtu.be/1_zQj1zbDYM | ||

| + | ^click on the link above to watch my individual project synopsis, Happy watching :) #stayconscious | ||

| + | |||

| + | |||

| + | == Class resume 03/03/2023 == | ||

| + | |||

| + | today we discuss pyrolisis, pyrolisi is a fuel that could be burned without or with less air, other conversion methods are gasification, liquefaction, and combustion. pyrolisis fuel examples: charcoal, air gas, oil. it needs drying methods before it will be continued to the reactor. to decompose we need a temperature of 300-350 c in the process | ||

| + | |||

| + | '''Pyrolisis Process''' | ||

| + | |||

| + | Pyrolisis is a thermo-chemical decomposition process that converts organic or inorganic materials into solid, liquid and gases products. The pyrolisis involves multiple complex chemical reactions, and the derived product are highly dependent on the pyrolisis operating parameters and type of feedback. The size of the cuts will effect on the heal product. | ||

| + | [[File:PYROLISIS.jpg|200px|thumb|center|today's class lecture]] | ||

| + | |||

| + | == DESALINASI == | ||

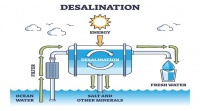

| + | Desalination is the process of removing salt from seawater or other salty water to produce fresh water that can be used for human purposes such as irrigation, consumption and industry. This process is carried out using different technologies, such as reverse osmosis, distillation and other methods. Desalination is a solution to the problem of shortage of fresh water in areas that have limited access to fresh water resources. Although desalination can produce more fresh water, this process requires significant costs and energy, so this technology is not very popular and not very commonly used. | ||

| + | In Indonesia, desalination is becoming increasingly important because the country has a limited amount of fresh water, especially in dry areas such as Bali, Lombok and parts of East Java. Currently, Indonesia has several ongoing or ongoing desalination projects. | ||

| + | |||

| + | One of the largest desalination projects in Indonesia is the Seawater Generator (PAL) in Bali. This project is a collaboration between the Governments of Indonesia and Japan which is expected to produce 120 thousand cubic meters of fresh water per day from sea water. In addition, on Nias Island, North Sumatra, a desalination plant has been built which can produce 30 thousand cubic meters of fresh water per day. | ||

| + | |||

| + | [[File:Desalination.jpg|200px|thumb|center|Desalination Flow]] | ||

| + | |||

| + | In addition to large projects, desalination has also begun to be used on a small scale in several villages and small islands in Indonesia. An example is in the village of Kalabahi, Alor Island, East Nusa Tenggara, where a simple desalination plant was built to provide clean water for the local population. | ||

| + | |||

| + | Nonetheless, desalination technology in Indonesia is still relatively expensive and not yet accessible to the wider community. In addition, the operation of a desalination plant also requires significant operational and maintenance costs. Therefore, there is a need for support and investment from the government and the private sector to expand the use of desalination technology in Indonesia. | ||

| + | |||

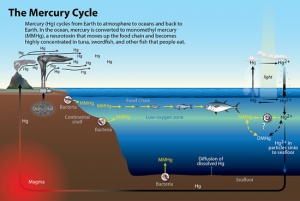

| + | [[File:Mercury.jpg|300px|thumb|center|Desalination Flow]] | ||

| + | |||

| + | Mercury is a toxic heavy metal that can be found in seawater and can pose a threat to the environment and human health. The presence of mercury in seawater can have negative impacts on the desalination process and the quality of the resulting water. | ||

| + | |||

| + | When mercury is present in seawater, it can accumulate in the reverse osmosis (RO) membranes, which are commonly used in desalination plants. This can lead to reduced membrane performance and efficiency, as well as increased maintenance requirements and costs. In addition, the presence of mercury in the RO concentrate, which is the brine that is produced during the desalination process, can also pose a threat to the marine environment if it is not disposed of properly. | ||

| + | |||

| + | Moreover, the high energy consumption in the desalination process can lead to the release of mercury into the atmosphere if the energy source used is not properly controlled or regulated. This can contribute to air pollution and further environmental impacts. | ||

| + | |||

| + | Therefore, it is important for desalination plants to monitor and control the levels of mercury in their feedwater and concentrate streams to ensure that the resulting water is safe for human consumption and the environment. The use of advanced treatment technologies and proper disposal methods for the RO concentrate can also help minimize the environmental impacts of mercury in the desalination process. | ||

| + | |||

| + | '''Graphene is a promising material''' for various applications, including water treatment and desalination. Its unique properties, such as high surface area, mechanical strength, and electrical conductivity, make it an ideal candidate for water filtration and purification. | ||

| + | |||

| + | Several studies have demonstrated the potential of graphene-based membranes for water treatment, particularly in desalination. Graphene oxide (GO) and reduced graphene oxide (rGO) membranes have shown high permeability and selectivity, allowing them to filter out salt and other impurities from seawater and brackish water. | ||

| + | |||

| + | One of the advantages of using graphene-based membranes for desalination is their ability to operate at a lower pressure and energy consumption than traditional desalination methods. This can potentially reduce the cost and environmental impact of desalination. | ||

| + | |||

| + | However, there are still some challenges to overcome before graphene-based membranes can be widely used in water treatment. One of the main challenges is the scalability of the production process, as current methods for producing graphene are expensive and time-consuming. In addition, the stability and durability of the graphene-based membranes under real-world conditions need to be further studied. | ||

| + | |||

| + | Overall, '''graphene-based membranes''' have great potential for improving access to clean drinking water, particularly in regions with limited freshwater resources. Ongoing research and development in this field could lead to more efficient and cost-effective desalination technologies in the future. | ||

| + | |||

| + | [[File:kuliahsiang.jpg|300px|thumb|center|Desalination Flow]] | ||

| + | |||

| + | |||

| + | == WORKSHOP STUDY VISIT == | ||

| + | |||

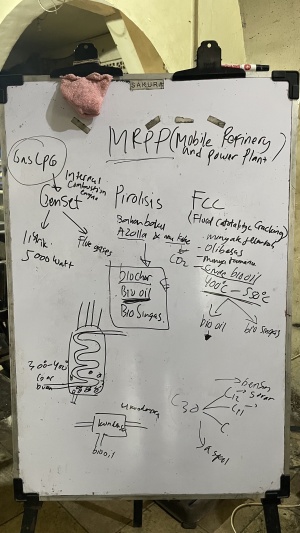

| + | On 10th of March 2023, our class visited CCIT workshop located at Kukusan street. We witnessed some of the mechanical projects that were made by Mr. DAI and the team. Tanwir as one of his team did explain the MRPP project which is a vehicle powered by biomass fuel. | ||

| + | [[File:studyvisit.jpg|300px|thumb|center|ECS CLASS STUDENTS]] | ||

| + | The picture down below, explains the workflow of the mobile refinery and power plant ( MRPP ) that consist of the generator, pyrolisis, and fluid catalytic cracking (fcc) for further information pay attention schematic to drown below | ||

| + | [[File:MRPP.jpg|300px|thumb|center|MRPP DIAGRAM]] | ||

| + | A mobile refinery is a portable oil refinery that can be transported to different locations to process crude oil into refined products, such as gasoline, diesel, and jet fuel. These refineries are often used in remote areas where it is not feasible to build a permanent refinery or in disaster areas where infrastructure has been damaged. | ||

| + | |||

| + | Mobile refineries are typically housed in shipping containers or trailers and can be transported by truck, rail, or ship. They can process a wide range of crude oils and can be configured to produce different grades of refined products based on local demand. | ||

| + | |||

| + | On the other hand, a power plant vehicle is a mobile electricity generation unit that can be used to provide temporary or emergency power to remote or disaster-stricken areas. These vehicles typically have generators and fuel tanks mounted on a trailer or truck chassis and can be quickly deployed to provide power to areas that have lost access to the electrical grid. | ||

| + | |||

| + | Power plant vehicles are used in a variety of applications, including disaster relief, construction sites, and outdoor events. They can be powered by a variety of fuels, including diesel, natural gas, and propane, and can generate electricity in a range of sizes, from a few kilowatts to several megawatts. | ||

| + | |||

| + | |||

| + | |||

| + | == CLASS PROJECT == | ||

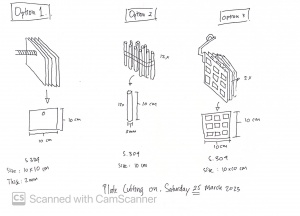

| + | [[File:PLATE.jpg|300px|thumb|center|3 Design options]] | ||

| + | |||

| + | In this project I would like to propose 3 design option in order to produce maximum amount of electrolysis bubbles | ||

| + | |||

| + | https://youtu.be/r8cv-nVBkuQ | ||

| + | |||

| + | |||

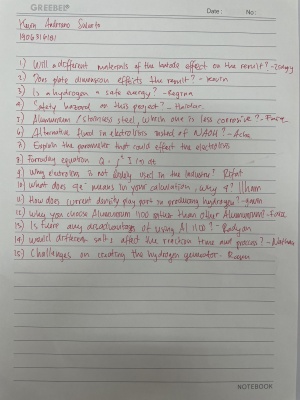

| + | == QUIZ 2 == | ||

| + | [[File:quizecs2.jpg|300px|thumb|center|quiz 2 questions]] | ||

| + | |||

| + | |||

| + | == UTS PROJECT REPORT == | ||

| + | |||

| + | Project Report file : https://docs.google.com/document/d/1ep-jkv28fqEEPWmSNkrS__aE9KWJPhxKtS_SUfeufVY/edit?usp=sharing | ||

| + | |||

| + | |||

| + | |||

| + | == FINAL PROJECT EXPERIMENT RESULT == | ||

| + | REPORT : https://docs.google.com/document/d/1ep-jkv28fqEEPWmSNkrS__aE9KWJPhxKtS_SUfeufVY/edit# | ||

| + | . | ||

| + | PRESENTATION : https://docs.google.com/presentation/d/1jObaJjVH4cn6m-Ra5Q-iNcKCv-N2Uea60n5DrEv3uMc/edit#slide=id.g229339270f5_0_0 | ||

Latest revision as of 20:00, 12 June 2023

Contents

INTRODUCTION

Name : Kevin Andriano Sularto

NPM : 1906316181

RELATIONSHIP BETWEEN SUGAR CANE COMPANY, AUTOMOTIVE COMPANY, AND OIL AND GAS COMPANY

There may be several ways to think about the relationship between a sugar cane factory, an automotive factory, and an oil and gas company, but here are a few possible perspectives: File:Sugar Industry-1.jpg Supply chain: Sugar cane, oil, and gas are all used as inputs in various industries, including automotive manufacturing. A sugar cane factory produces sugar, which can be used to make ethanol, a biofuel that can be blended with gasoline. Oil and gas companies produce the gasoline and other petroleum-based products that are used to power vehicles. An automotive factory uses both biofuels and petroleum-based fuels to power the cars it produces. Therefore, there is a supply chain relationship between these industries.

Economic interdependence: Sugar cane, automotive, and oil and gas companies are all part of the global economy, and their success is interconnected. For example, if there is a spike in oil prices, it can increase the cost of transportation for sugar cane and other raw materials, which can in turn affect the profitability of a sugar cane factory. Similarly, if there is a downturn in the automotive industry, it can decrease the demand for fuel, which can affect the profitability of oil and gas companies. Thus, there is an economic interdependence between these industries.

Environmental impact: Sugar cane factories, automotive factories, and oil and gas companies can all have significant environmental impacts. For example, sugar cane production can lead to deforestation and habitat destruction, while automotive factories and oil and gas companies can contribute to air and water pollution and greenhouse gas emissions. Therefore, there is a shared responsibility among these industries to minimize their environmental footprint and work towards sustainability.

Overall, the relationship between a sugar cane factory, an automotive factory, and an oil and gas company is complex and multifaceted, and can be examined from various angles.

INDIVIDUAL PROJECT

HYBRID DIESEL VEHICLE / HYBRID GASOLINE VEHICLE / ELECTRIC VEHICLE. WHICH ONE IS BETTER?

A hybrid diesel vehicle is a type of hybrid vehicle that uses a combination of a diesel engine and an electric motor to power the vehicle. In this type of vehicle, the diesel engine works in tandem with an electric motor and battery to provide propulsion and improve fuel efficiency.

The electric motor in a hybrid diesel vehicle can be used in different ways, depending on the design of the vehicle. For example, in some hybrid diesel vehicles, the electric motor is used to assist the diesel engine during acceleration, providing additional power to the wheels and reducing the load on the diesel engine. This can help to improve fuel efficiency and reduce emissions.

In other hybrid diesel vehicles, the electric motor can be used to power the vehicle on its own at low speeds, such as in stop-and-go traffic, while the diesel engine takes over at higher speeds or when more power is needed. This can help to improve fuel efficiency in city driving conditions, where the vehicle spends a lot of time idling and accelerating slowly.

Hybrid diesel vehicles can provide a number of benefits, including improved fuel efficiency, reduced emissions, and increased performance. They are often used in commercial and industrial applications, such as buses and delivery trucks, where fuel efficiency and environmental impact are important factors. However, they can also be used in passenger cars and SUVs, providing a greener and more efficient alternative to traditional gasoline or diesel engines.

VIDEO SYNOPSIS

https://youtu.be/1_zQj1zbDYM ^click on the link above to watch my individual project synopsis, Happy watching :) #stayconscious

Class resume 03/03/2023

today we discuss pyrolisis, pyrolisi is a fuel that could be burned without or with less air, other conversion methods are gasification, liquefaction, and combustion. pyrolisis fuel examples: charcoal, air gas, oil. it needs drying methods before it will be continued to the reactor. to decompose we need a temperature of 300-350 c in the process

Pyrolisis Process

Pyrolisis is a thermo-chemical decomposition process that converts organic or inorganic materials into solid, liquid and gases products. The pyrolisis involves multiple complex chemical reactions, and the derived product are highly dependent on the pyrolisis operating parameters and type of feedback. The size of the cuts will effect on the heal product.

DESALINASI

Desalination is the process of removing salt from seawater or other salty water to produce fresh water that can be used for human purposes such as irrigation, consumption and industry. This process is carried out using different technologies, such as reverse osmosis, distillation and other methods. Desalination is a solution to the problem of shortage of fresh water in areas that have limited access to fresh water resources. Although desalination can produce more fresh water, this process requires significant costs and energy, so this technology is not very popular and not very commonly used. In Indonesia, desalination is becoming increasingly important because the country has a limited amount of fresh water, especially in dry areas such as Bali, Lombok and parts of East Java. Currently, Indonesia has several ongoing or ongoing desalination projects.

One of the largest desalination projects in Indonesia is the Seawater Generator (PAL) in Bali. This project is a collaboration between the Governments of Indonesia and Japan which is expected to produce 120 thousand cubic meters of fresh water per day from sea water. In addition, on Nias Island, North Sumatra, a desalination plant has been built which can produce 30 thousand cubic meters of fresh water per day.

In addition to large projects, desalination has also begun to be used on a small scale in several villages and small islands in Indonesia. An example is in the village of Kalabahi, Alor Island, East Nusa Tenggara, where a simple desalination plant was built to provide clean water for the local population.

Nonetheless, desalination technology in Indonesia is still relatively expensive and not yet accessible to the wider community. In addition, the operation of a desalination plant also requires significant operational and maintenance costs. Therefore, there is a need for support and investment from the government and the private sector to expand the use of desalination technology in Indonesia.

Mercury is a toxic heavy metal that can be found in seawater and can pose a threat to the environment and human health. The presence of mercury in seawater can have negative impacts on the desalination process and the quality of the resulting water.

When mercury is present in seawater, it can accumulate in the reverse osmosis (RO) membranes, which are commonly used in desalination plants. This can lead to reduced membrane performance and efficiency, as well as increased maintenance requirements and costs. In addition, the presence of mercury in the RO concentrate, which is the brine that is produced during the desalination process, can also pose a threat to the marine environment if it is not disposed of properly.

Moreover, the high energy consumption in the desalination process can lead to the release of mercury into the atmosphere if the energy source used is not properly controlled or regulated. This can contribute to air pollution and further environmental impacts.

Therefore, it is important for desalination plants to monitor and control the levels of mercury in their feedwater and concentrate streams to ensure that the resulting water is safe for human consumption and the environment. The use of advanced treatment technologies and proper disposal methods for the RO concentrate can also help minimize the environmental impacts of mercury in the desalination process.

Graphene is a promising material for various applications, including water treatment and desalination. Its unique properties, such as high surface area, mechanical strength, and electrical conductivity, make it an ideal candidate for water filtration and purification.

Several studies have demonstrated the potential of graphene-based membranes for water treatment, particularly in desalination. Graphene oxide (GO) and reduced graphene oxide (rGO) membranes have shown high permeability and selectivity, allowing them to filter out salt and other impurities from seawater and brackish water.

One of the advantages of using graphene-based membranes for desalination is their ability to operate at a lower pressure and energy consumption than traditional desalination methods. This can potentially reduce the cost and environmental impact of desalination.

However, there are still some challenges to overcome before graphene-based membranes can be widely used in water treatment. One of the main challenges is the scalability of the production process, as current methods for producing graphene are expensive and time-consuming. In addition, the stability and durability of the graphene-based membranes under real-world conditions need to be further studied.

Overall, graphene-based membranes have great potential for improving access to clean drinking water, particularly in regions with limited freshwater resources. Ongoing research and development in this field could lead to more efficient and cost-effective desalination technologies in the future.

WORKSHOP STUDY VISIT

On 10th of March 2023, our class visited CCIT workshop located at Kukusan street. We witnessed some of the mechanical projects that were made by Mr. DAI and the team. Tanwir as one of his team did explain the MRPP project which is a vehicle powered by biomass fuel.

The picture down below, explains the workflow of the mobile refinery and power plant ( MRPP ) that consist of the generator, pyrolisis, and fluid catalytic cracking (fcc) for further information pay attention schematic to drown below

A mobile refinery is a portable oil refinery that can be transported to different locations to process crude oil into refined products, such as gasoline, diesel, and jet fuel. These refineries are often used in remote areas where it is not feasible to build a permanent refinery or in disaster areas where infrastructure has been damaged.

Mobile refineries are typically housed in shipping containers or trailers and can be transported by truck, rail, or ship. They can process a wide range of crude oils and can be configured to produce different grades of refined products based on local demand.

On the other hand, a power plant vehicle is a mobile electricity generation unit that can be used to provide temporary or emergency power to remote or disaster-stricken areas. These vehicles typically have generators and fuel tanks mounted on a trailer or truck chassis and can be quickly deployed to provide power to areas that have lost access to the electrical grid.

Power plant vehicles are used in a variety of applications, including disaster relief, construction sites, and outdoor events. They can be powered by a variety of fuels, including diesel, natural gas, and propane, and can generate electricity in a range of sizes, from a few kilowatts to several megawatts.

CLASS PROJECT

In this project I would like to propose 3 design option in order to produce maximum amount of electrolysis bubbles

QUIZ 2

UTS PROJECT REPORT

Project Report file : https://docs.google.com/document/d/1ep-jkv28fqEEPWmSNkrS__aE9KWJPhxKtS_SUfeufVY/edit?usp=sharing

FINAL PROJECT EXPERIMENT RESULT

REPORT : https://docs.google.com/document/d/1ep-jkv28fqEEPWmSNkrS__aE9KWJPhxKtS_SUfeufVY/edit# . PRESENTATION : https://docs.google.com/presentation/d/1jObaJjVH4cn6m-Ra5Q-iNcKCv-N2Uea60n5DrEv3uMc/edit#slide=id.g229339270f5_0_0