Difference between revisions of "Thareq Wibisono"

(→10 March 2021) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 90: | Line 90: | ||

| − | == 10 March 2021 == | + | == Date: 10 March 2021 == |

In the last class session, we have a change to practice OpenModelica to simulate and interpret the result combustion chamber simulation. The simulation procedure is similar to those in compressor but the difference lies in the components used. | In the last class session, we have a change to practice OpenModelica to simulate and interpret the result combustion chamber simulation. The simulation procedure is similar to those in compressor but the difference lies in the components used. | ||

| Line 108: | Line 108: | ||

Unlike the compressor where the air composition remain the same as discussed in 9 March 2021 wiki, the component model of combustion chamber involve the chemical reaction between the air composition from the flue gasses source and the fuel source. Thus, the outlet air composition that will be feed to the combustion turbine will differ from the initial value. | Unlike the compressor where the air composition remain the same as discussed in 9 March 2021 wiki, the component model of combustion chamber involve the chemical reaction between the air composition from the flue gasses source and the fuel source. Thus, the outlet air composition that will be feed to the combustion turbine will differ from the initial value. | ||

| − | The components mention before can be found in the ThermoSysPro libraries which can be drag and drop to the diagram view of the model and connected to each other to closed the equation inside the ''GT(Gas Turbine)CombustionChamber''. It is worth noting, however, that each ''GT(Gas Turbine)CombustionChamber'' input correspond to a different source type. There are 3 source type which is the flue gasses, the water steam, and the fuel source as mention in the component list and each of the source type is connected to the corresponding inlet within the combustion chamber as shown in Figure | + | The components mention before can be found in the ThermoSysPro libraries which can be drag and drop to the diagram view of the model and connected to each other to closed the equation inside the ''GT(Gas Turbine)CombustionChamber''. It is worth noting, however, that each ''GT(Gas Turbine)CombustionChamber'' input correspond to a different source type. There are 3 source type which is the flue gasses, the water steam, and the fuel source as mention in the component list and each of the source type is connected to the corresponding inlet within the combustion chamber as shown in Figure 7 below |

| + | [[File:Combustion chamber.PNG|800px|thumb|center|'''Figure 7.''' The diagram view of the combustion chamber system including the water steam source (''Top left''), the flue gasses source (''centre left''), and the fuel source (''bottom left'')]] | ||

| + | Because the simulation involve 3 different source, the input of the simulation also differ from those in compressor which are summarized below: | ||

| − | the | + | - Flue gases temperature at the outlet of the boiler = 386.16 K |

| − | + | - Flue gases pressure at the outlet of the boiler = 14.1e+5 Pa | |

| + | |||

| + | - Thermal power losses = 106 W | ||

| + | |||

| + | - Air pressure at the inlet of the combustion chamber = 15e+5 Pa | ||

| + | |||

| + | - Air temperature at the inlet = 680 K | ||

| + | |||

| + | - Air mass flow rate at the inlet = 415 kg/s | ||

| + | |||

| + | - CO2 mass fraction in the air at the inlet = 0 | ||

| + | |||

| + | - H2O mass fraction in the air at the inlet = 0.01 | ||

| + | |||

| + | - O2 mass fraction in the air at the inlet = 0.23 | ||

| + | |||

| + | - SO2 mass fraction in the air at the inlet = 0 | ||

| + | |||

| + | - Fuel temperature at the inlet = 410 K | ||

| + | |||

| + | - Fuel mass flow rate at the inlet = 9.3 kg/s | ||

| + | |||

| + | - Lower heating value of the fuel = 47.5e+6 J/kg | ||

| + | |||

| + | - Fuel humidity = 0 | ||

| + | |||

| + | - C mass fraction in the fuel = 0.755 | ||

| + | |||

| + | - H mass fraction in the fuel = 0.245 | ||

| + | |||

| + | - Fuel specific heat capacity = 2255 J/kg/K | ||

| + | |||

| + | - Fuel density = 0.838 kg/m3. | ||

| + | |||

| + | The result of the simulation with the aforementioned input is shown below | ||

| + | |||

| + | [[File:Combustion chamber R1.PNG|800px|thumb|center|'''Figure 8.''' The first attempt result of the combustion chamber simulation]] | ||

| + | |||

| + | It worth noting that the above simulation runs with zero mass flow rate of the water steam to the combustion chamber. Thus, I try to make an experiment out of it to see whether the result will change particularly the air composition, the temperature and the flue gasses mass flow rate. The second attempt result is shown below where I increase the mass flow rate of the water steam to 50 Kg/s | ||

| + | |||

| + | [[File:Combustion chamber R2.PNG|800px|thumb|center|'''Figure 9.''' The second attempt result of the combustion chamber simulation]] | ||

| + | |||

| + | The second attempt result clearly show that the air composition is changing. The mass flow rate of the flue gasses also shows a slight increase from 424 Kg/s to 474 Kg/s. In contrast, the temperature of the flue gasses is decreasing significantly which shows that increasing the water steam mass flow rate will decrease the outlet flue gasses temperature. | ||

| + | |||

| + | There are a lot of things that needs to be learn from the experiment above because I only change only one parameter from one type of the source. Thus, the knowledge of the governing GT combustion chamber equation is needed to find more correlation between each parameter and its output which is still in the process so I can not write it down yet. | ||

Latest revision as of 15:34, 10 March 2021

Contents

Date: 23 February 2021

Today I have learn about the correlation between justice and its usage in our current mechanical knowledge. Although it is rather an odd correlation as justice refers to the socio-economic term, the meaning of justice itself express the state of equilibrium in which one does not have to do another work to balance out the inequalities. As an engineer, justice is important not only to uphold social inequalities but also, in a more technical sense, an obligatory to understand how physical system works through a mathematical equations. Any physical system will find its own way to reach a state of equilibrium by increasing its entropy. By the time it reach the state of equilibrium, the entropy will reach its maximum level and any entities within the mathematical equation will balanced out.

But before dwell deeper to the topic, a simple definition to energy must be provided as many still have a vague idea about the term. The energy can be explained as the ability to do work, as one of my classmate says. It is a mechanism that structured life. like the flowing water, the energy is not stagnant. It constantly deliver one self to another entities in a various form. For example when we do an activity, we tend to be in exhaustion state by running a few kilometers as the energy is flowing from the chemical energy in our body to mechanical energy by moving our leg and dissipated as heat to the environment.

Date: 24 February 2021

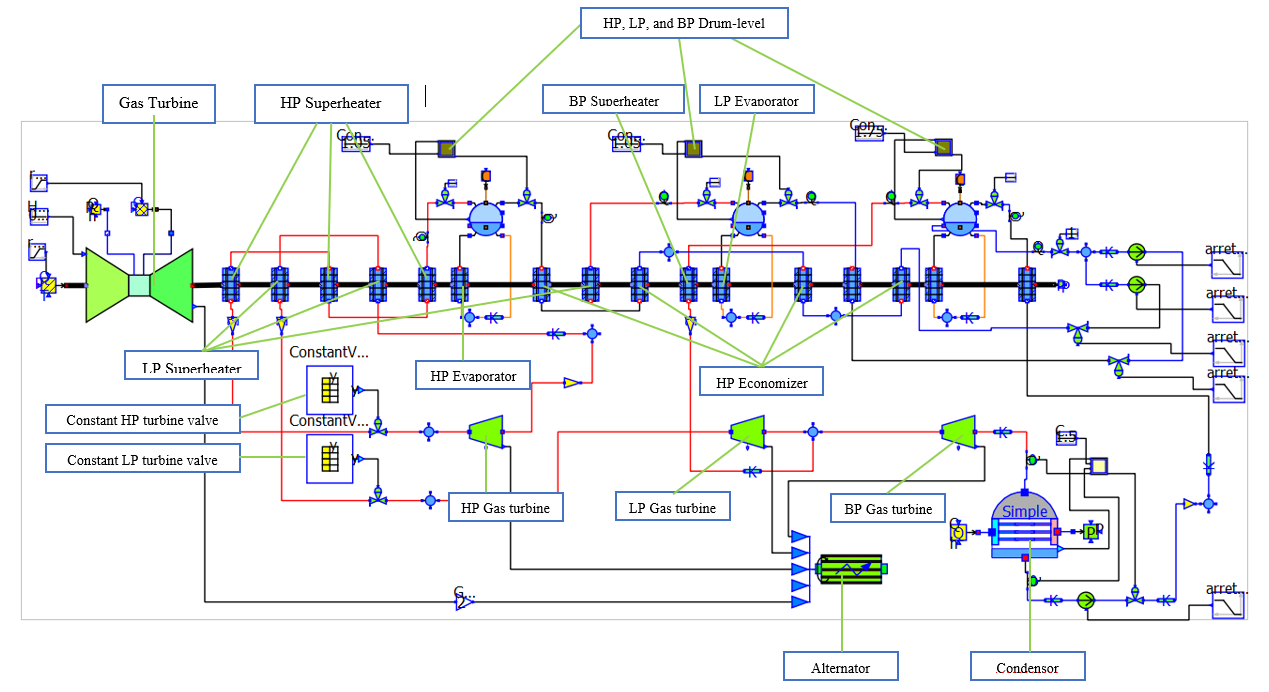

The assignment given yesterday is to define the component of the combined cycle plant which are shown below

Date: 2 March 2021

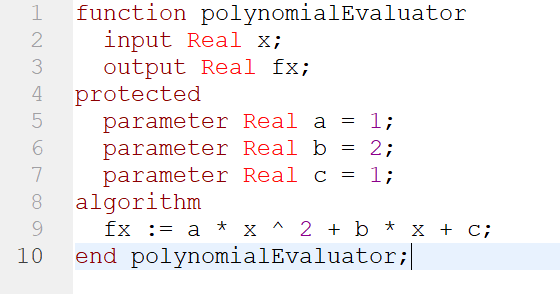

Last session of the class we are given a task to learn the open-modelica software as to get the general workflow of the software and its feeling. The main learning source for my learning journey is via youtube and a website titled "Modelica by Example" created by Dr. Michael M. Tiller. I began my journey with the familiarity of modelica language which is the driving program for the software. The syntax of the program, like most of the available high-language program, contain a familiar properties such as the if, elif, and else statement, iteration with for and while loop, variable declaration, array, etc. I tried to play around with the language and manage to write several interesting program. One of those is a function that return a calculation of a polynomial algebaric expression. The script is shown below

As you can see form the script, the function takes x as the input and return fx as the output. The parameter (variable that remain constant through out the simulation) is written below the protected statement which include the polynomial constant a, b, and c. Because we are dealing with the Real number, we must specified it after typing the parameter. The algorithm statement will carry out the actual evaluation which in this case will return fx as the output

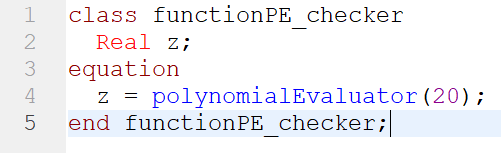

Because it is a function, it cannot be simulated directly. So I create a new class, which are able to call and simulate the function, with the following script

which will return the following result

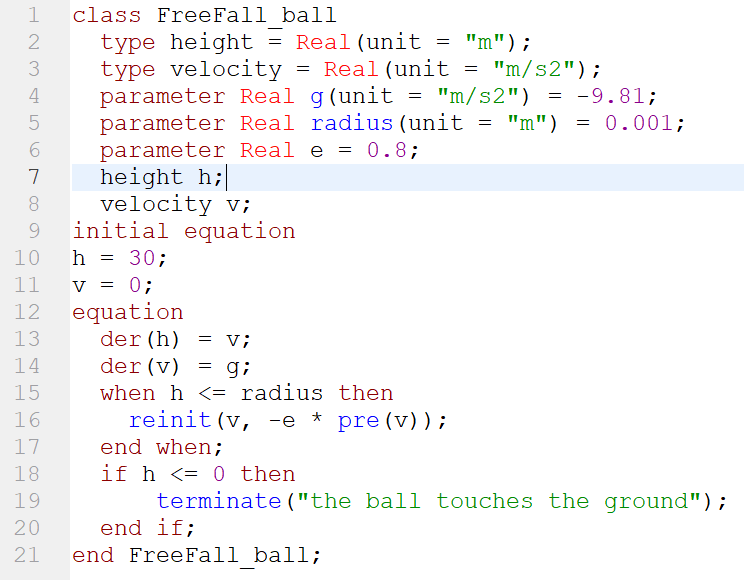

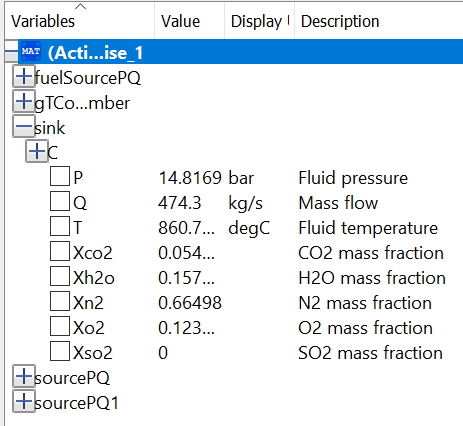

Another program that I write is the bouncing ball program which calculate the bouncing trajectory of a free falling ball when hitting the ground. The script to the program is shown below

In short the program will try to calculate the trajectory and the velocity of the ball. When the ball is bounced back, the velocity is decrease by a constant e. When the ball reach 0 m in height, the program will terminate. The resulting plot is shown below

Date: 9 March 2021

Last week, we are given an assignment to investigate the parameter used for a gas turbine cycle in Open-Modelica software. My journey started by investigating the main component of the the gas turbine cycle which include the compressor, the combustion turbine, and the combustion chamber. Albeit the initial plan to investigate all of the component, I only able to investigate the input and output parameter of the compressor that are specific for the ThermoSysPro libraries which will be discussed below.

Compressor

Compressor is a device that are responsible to compress air to increase the pressure and temperature of the upstream air up to a certain point depending on the compressor unit specification. Because we idealized the system to be isentropic (adiabatic and reversible), there exist isentropic efficiency (tau) to relate the actual power and the idealized power. In ThermalSysPro system, there are several input that must be considered which are:

1. Inlet and outlet pressure (Pi and Po)

2. Inlet mass flow rate (m_dot)

3. Nominal compression rate

4. Inlet and outlet air temperature (Ti and To)

5. Air composition (XCO2, XO2, XH20, XSO2)

6. Nominal isentropic efficiency

It is worth mention, that the air composition will remain constant through out the process as there are no chemical reaction (combustion) occurring within the compressor. The parameter mention above will be used to calculate the power required for the compressor which have the following governing equation

W_cp = m_dot * (hi - ho)

As we can see from the equation above, we do not know the inlet and outlet specific enthalpy (hi and ho). The inlet specific enthalpy can be calculated by taking the Pi, Ti, and the air composition (XCO2, XO2, XH20, XSO2) using the following governing equation:

h = u * (Pi / rho_i)

in which u is the specific energy and rho_i is the inlet density which can be calculated by taking into account the inlet temperature (Ti) and the air composition which will not be discussed in this today's wiki. Meanwhile, the oulet specific enthalpy can be calculated by using the relation between the specific enthalpy and the isentropic efficiency (tau) by using the following equation:

tau = (his - hi) / (ho - hi)

which can be modified as:

ho = hi + ((his - hi) / tau)

in which his his is the isentropic specific enthalpy that take into account the outlet pressure Po, the isentropic temperature (Tis) and the air composition.

Although there are a lot of things I have been learn about the compressor, I still have a confusion regarding the calculation of the isentropic efficiency for the compressor in the ThermoSysPro libraries.

Date: 10 March 2021

In the last class session, we have a change to practice OpenModelica to simulate and interpret the result combustion chamber simulation. The simulation procedure is similar to those in compressor but the difference lies in the components used.

There are several components that plays an important role in the simulation listed below:

1. The GT(Gas Turbine)CombustionChamber

2. SourcePQ (Pressure and mass flow is fixed) component for the flue gasses

3. Sink component for the flue gasses

4. SourcePQ (Pressure and mass flow is fixed) for the water steam

5. FuelSourcePQ (Pressure and mass flow is fixed) for the fuel

Unlike the compressor where the air composition remain the same as discussed in 9 March 2021 wiki, the component model of combustion chamber involve the chemical reaction between the air composition from the flue gasses source and the fuel source. Thus, the outlet air composition that will be feed to the combustion turbine will differ from the initial value.

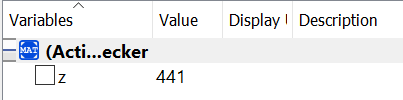

The components mention before can be found in the ThermoSysPro libraries which can be drag and drop to the diagram view of the model and connected to each other to closed the equation inside the GT(Gas Turbine)CombustionChamber. It is worth noting, however, that each GT(Gas Turbine)CombustionChamber input correspond to a different source type. There are 3 source type which is the flue gasses, the water steam, and the fuel source as mention in the component list and each of the source type is connected to the corresponding inlet within the combustion chamber as shown in Figure 7 below

Because the simulation involve 3 different source, the input of the simulation also differ from those in compressor which are summarized below:

- Flue gases temperature at the outlet of the boiler = 386.16 K

- Flue gases pressure at the outlet of the boiler = 14.1e+5 Pa

- Thermal power losses = 106 W

- Air pressure at the inlet of the combustion chamber = 15e+5 Pa

- Air temperature at the inlet = 680 K

- Air mass flow rate at the inlet = 415 kg/s

- CO2 mass fraction in the air at the inlet = 0

- H2O mass fraction in the air at the inlet = 0.01

- O2 mass fraction in the air at the inlet = 0.23

- SO2 mass fraction in the air at the inlet = 0

- Fuel temperature at the inlet = 410 K

- Fuel mass flow rate at the inlet = 9.3 kg/s

- Lower heating value of the fuel = 47.5e+6 J/kg

- Fuel humidity = 0

- C mass fraction in the fuel = 0.755

- H mass fraction in the fuel = 0.245

- Fuel specific heat capacity = 2255 J/kg/K

- Fuel density = 0.838 kg/m3.

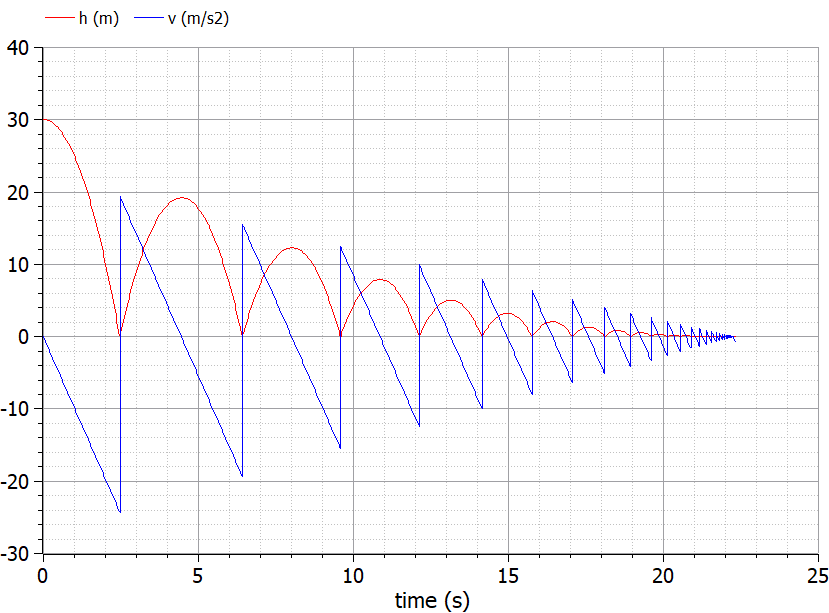

The result of the simulation with the aforementioned input is shown below

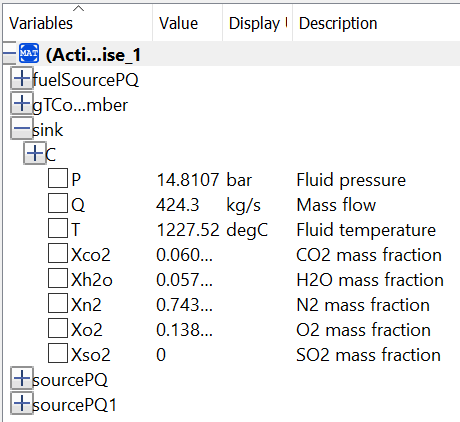

It worth noting that the above simulation runs with zero mass flow rate of the water steam to the combustion chamber. Thus, I try to make an experiment out of it to see whether the result will change particularly the air composition, the temperature and the flue gasses mass flow rate. The second attempt result is shown below where I increase the mass flow rate of the water steam to 50 Kg/s

The second attempt result clearly show that the air composition is changing. The mass flow rate of the flue gasses also shows a slight increase from 424 Kg/s to 474 Kg/s. In contrast, the temperature of the flue gasses is decreasing significantly which shows that increasing the water steam mass flow rate will decrease the outlet flue gasses temperature.

There are a lot of things that needs to be learn from the experiment above because I only change only one parameter from one type of the source. Thus, the knowledge of the governing GT combustion chamber equation is needed to find more correlation between each parameter and its output which is still in the process so I can not write it down yet.