|

|

| (2 intermediate revisions by the same user not shown) |

| Line 1: |

Line 1: |

| − | '''The application of loop-seals for the catalyst transfer to the Riser on pilot-plant FCC applying gas-particle simulation using MMPIC method'''

| |

| | | | |

| − | =='''Abstract'''==

| + | [[File:0001.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | Computational fluid dynamics (CFD) is robust in predicting and analyzing complex multiphase flow hydrodynamics, especially on fluid catalytic cracking (FCC) phenomena in fluid-solid reaction. This study presented the replacement sliding valve as a regulator of the catalyst distribution to the Riser in a pilot-scale fluid catalytic cracking (FCC). Pilot-plant FCC is not possible to use a sliding valve because the pipe diameter is small and catalyst often clogged in the sliding valve wall. Therefore, the study depicts loop-seal as replacing the sliding valve for the control catalyst to the Riser. Furthermore, the paper describes particle catalyst distribution as employing loop-seal adopting the hydrodynamic approach with the Multiphase Particle-in-cell method (MP-PIC). This method applied three different drag models, the interphase drag model, Wen-Yu Drag Model, and Wen-Yu / Ergun Blend Drag Model, regarding the catalyst drops from the regenerator and the air blow to adjust the catalyst the Riser, which is the catalyst based on Region A 'Miyauchi. The result describes the difference in particle distribution using the three drag models.

| + | [[File:0002.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | Keywords: Computational Fluid Dynamics, CFD-MPPIC, Loop-seal, catalyst, FCC.

| + | [[File:0003.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | ==1. Introduction==

| + | [[File:0004.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | During 2019 Indonesia reached 51.8 million tons of CPO. From this source, it is processed into green fuel. Before becoming Green Fuel, CPO is processed first to become Refined Bleached Deodorized Palm Oil (RBDPO) next processed utilising the Fluid Catalytic Cracking method (FCC). The FCC unit process consists of the feed injection system, Riser, riser outlet separator system, disengager/stripper, regenerator, catalyst cooler (optional), catalyst withdrawal well, catalyst transfer lines, and control systems. The main processing products for RBDPO using the FCC are Gasoline, LCO (light cycle oil) and LPG.

| + | [[File:0005.jpg|1000px|thumb|left|alt text]] |

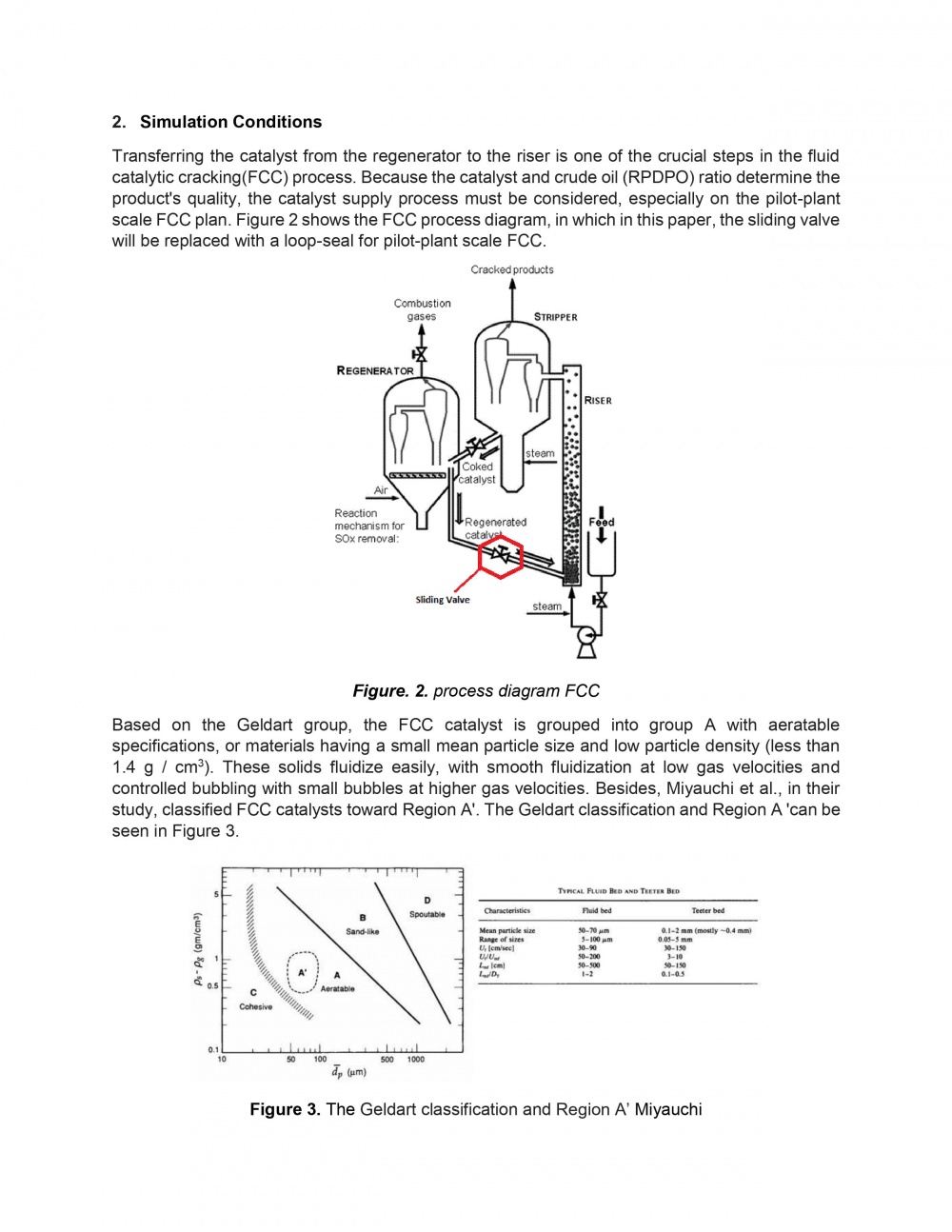

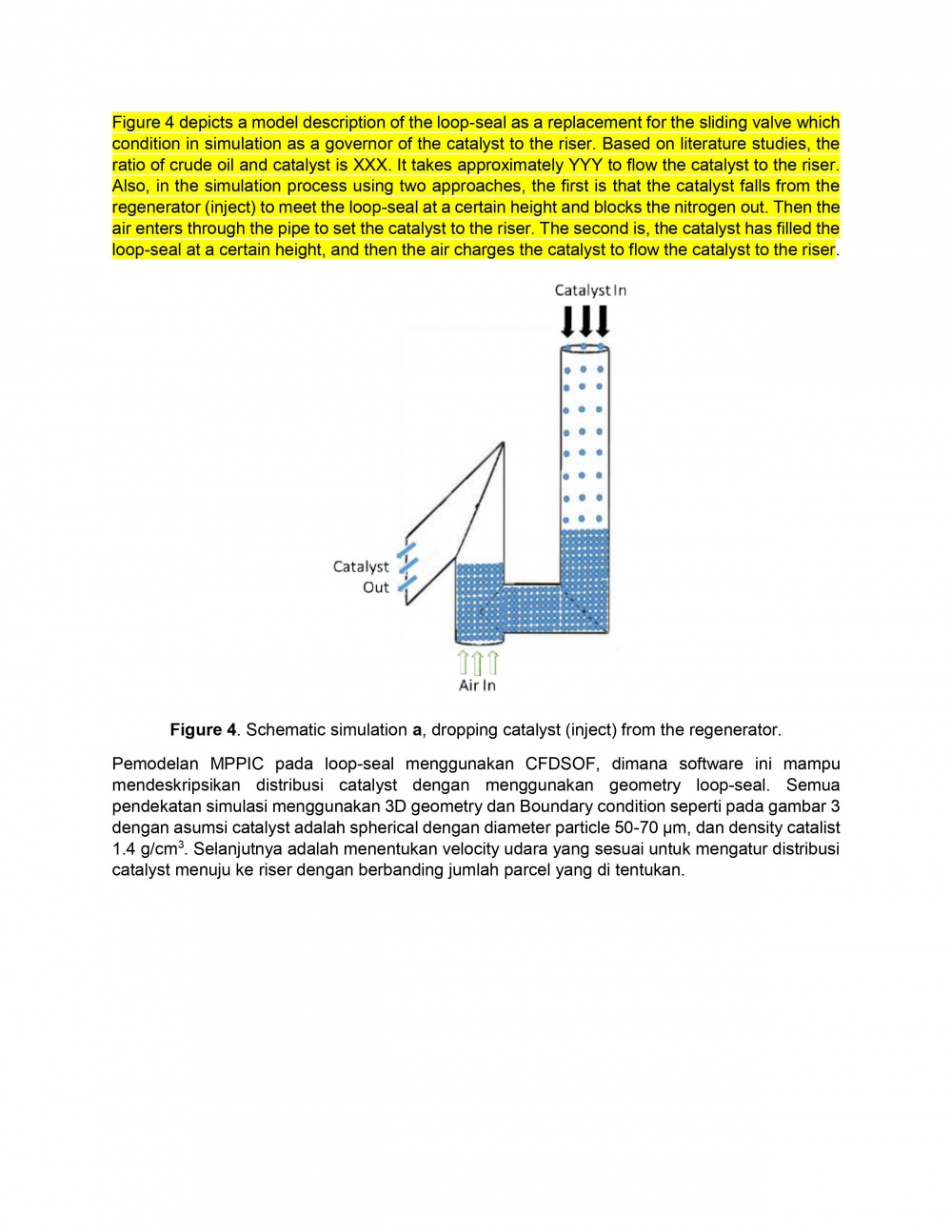

| − | The FCC process is a hydrocarbon reaction between crude oil (RBDPO) and a catalyst based on Particles' Geldart Classification. The proper selection of catalyst is essential to successful residue cracking operations. The importance of magnifies as the percentage of residual oil increases in the feedstock. Several properties of the catalyst should be examined for a particular feed. The properties are, Zeolite content, Micro-activity, Rare earth content, Unit cell size, Coke selectivity, Particle size distribution, Bulk density, Thermal stability, Surface area, Pore volume and pore distribution (strippability), Attrition resistance, Metals resistance, Gasoline octane properties. Regenerator and Riser are equipment that determines the FCC's product yield. This paper describes the transport of catalysts from the regenerator to the Riser.

| |

| | | | |

| − | Hydrodynamics through the Computational Fluid Dynamics (CFD) depicts the phenomenon of catalysts in the FCC. There are several types of gas and particle simulation approaches Eulerian, MPPIC, and DEM. Each type of method has its characteristics in solving gas-particle problems. MPPIC is the best an approach with the parcel in cell where the solids model tracks the position and trajectory of computational parcels, statistical groups of particles that share the same physical characteristics (e.g. diameter and density). Different diameter particles of the same material must be defined as separate solid phases in the present formulation, each with its statistical classification. This paper applies CFDSOF as a tool to calculate the catalyst phenomenon in the FCC.

| + | [[File:0006.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | The multiphase particle-in-cell (MP-PIC) is the numerical methods for predicting dense gas-solids flow. The gas-phase is treated as a continuum in the Eulerian reference frame. The solids are modelled in the Lagrangian reference frame tracking computational particles. The MPPIC is a derivative of the Particle-in-Cell (PIC) method for multiphase flows. The method employs a fixed Eulerian grid, and Lagrangian parcels are used to transport mass, momentum, and energy through this grid in a way that preserves the identities of the different materials associated with the particles. The main distinction with traditional Eulerian-Lagrangian methods is that the particles' interactions are calculated on the Eulerian grid. The Eulerian-Lagrangian method and the multiphase particle in cell (MPPIC) method have been used in this study. The model of the MPPIC is a Model Collision in CFDSOF, first of all, PIC models are derived from a Liouville equation describing the time evolution of a particle distribution function.

| + | [[File:0007.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | '''1.1 Mathematical model MPPIC'''

| + | [[File:0008.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | Mathematical models of separated particulate multiphase flow have used either a continuum approach for all phases [1, 2] or a continuum for the fluid and a Lagrangian model for particles [3]. The continuum–continuum model readily allows modeling of particle–particle stresses in dense particle flows using spatial gradients of particle volume fractions [2, 4]. However, modeling a distribution of types and sizes of particles complicates the continuum formulation because separate continuity and momentum equations must be solved for each size and type [4, 5]. Using a continuum model for the fluid phase and a Lagrangian model for the particle phase allows economical solution for flows with a wide range of particle types, sizes, shapes, and velocities [4, 6]. However, the collision frequency is high for volume fractions above 5% and cannot be realistically resolved by current Lagrangian collision calculations [6].

| + | [[File:0009.jpg|1000px|thumb|left|alt text]] |

| | | | |

| − | Particle-in-cell (PIC) methods have been used since the 1960s [7]. Fluids are represented by discrete mass points. The differential conservation equations of mass, momentum, and energy govern the flow, although the conservation of mass is satisfied by the summation of mass points in a computational cell. Nontransport terms are calculated from the differential equations, and the transport terms are calculated from mass points moving by a velocity weighting procedure. The initial motivation for PIC methods was probably the accuracy in following interfaces.

| + | [[File:0010.jpg|1000px|thumb|left|alt text]] |

| − | | |

| − | '''A. Continuum Phase.'''

| |

| − | The continuity equation for the fluid with no interphase mass transfer is:

| |

| − | | |

| − | [[File:1pic.JPG|800px|thumb|centre|alt text]] | |

| − | | |

| − | The fluid phase is incompressible and fluid and particle phases are isothermal. The momentum equation presented here neglects viscous molecular diffusion in the fluid but retains the viscous drag between particles and fluid through the interphase drag force, F. Neglecting the laminar fluid viscous terms generally has negligible effect on dense particle flow, and laminar terms can be easily included in the fluid equation set. The discrete particle to fluid momentum transfer (which is a turbulent closure model for subgrid momentum transfer between particles and fluid) generally produces low Reynolds numbers (based on particle diameter) and provides an excellent prediction of dense particle flows over a wide range of gas flow.

| |