Difference between revisions of "'''1. What is FCC?'''"

Agus.nuryadi (talk | contribs) |

Agus.nuryadi (talk | contribs) (→Background) |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | == Background == | |

| − | FCC | + | The process of the FCC unit consists of the feed injection system, riser, riser outlet separator system, disengager/stripper, regenerator, catalyst cooler (optional), catalyst withdrawal well, catalyst transfer lines, and control systems. |

| − | + | [[File:FCCdiagram.png|700px|thumb|centre|alt text]] | |

| + | |||

| + | |||

| + | The feed mixture is pumped to the base of the riser and divided into equal flows, to each of the feed nozzles. The feed, which has been preheated, is finely atomized and mixed with dispersion steam in the feed nozzles and injected into the riser. The small droplets of feed contact hot regenerated catalyst in a counter-current way and vaporize immediately. The vaporized oil intimately mixes with the catalyst particles and cracks into lighter, more valuable products along with slurry oil, coke, and gas. The product vapors travel up the riser while carrying the catalyst. Residence time in the riser is approximately 2 seconds at design conditions. The specially designed feed injection system ensures the reaction is carried out efficiently to minimize the production of coke, gas, and slurry oil. | ||

| + | please see the link below for a full explanation | ||

| − | + | http://air.eng.ui.ac.id/index.php?title=Fluid_catalytic_cracking_Plant | |

Latest revision as of 13:16, 8 December 2020

Background

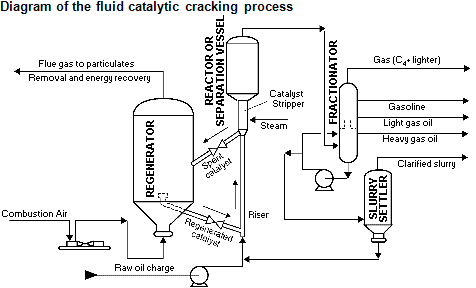

The process of the FCC unit consists of the feed injection system, riser, riser outlet separator system, disengager/stripper, regenerator, catalyst cooler (optional), catalyst withdrawal well, catalyst transfer lines, and control systems.

The feed mixture is pumped to the base of the riser and divided into equal flows, to each of the feed nozzles. The feed, which has been preheated, is finely atomized and mixed with dispersion steam in the feed nozzles and injected into the riser. The small droplets of feed contact hot regenerated catalyst in a counter-current way and vaporize immediately. The vaporized oil intimately mixes with the catalyst particles and cracks into lighter, more valuable products along with slurry oil, coke, and gas. The product vapors travel up the riser while carrying the catalyst. Residence time in the riser is approximately 2 seconds at design conditions. The specially designed feed injection system ensures the reaction is carried out efficiently to minimize the production of coke, gas, and slurry oil.

please see the link below for a full explanation

http://air.eng.ui.ac.id/index.php?title=Fluid_catalytic_cracking_Plant