Difference between revisions of "Artha Danaraja Dewantoro"

(→Presentation of my Hydrogen Storage System Design and Optimization) |

|||

| (18 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

== Introduction == | == Introduction == | ||

Nama saya Artha Danaraja Dewantoro dengan NPM 2106731106, lahir pada tanggal 11 April 2003 di Jakarta Selatan. Saya berdomisili di Bintaro, Tangerang Selatan dengan keluarga saya. Saya mahasiswa semester 4 Teknik Perkapalan. | Nama saya Artha Danaraja Dewantoro dengan NPM 2106731106, lahir pada tanggal 11 April 2003 di Jakarta Selatan. Saya berdomisili di Bintaro, Tangerang Selatan dengan keluarga saya. Saya mahasiswa semester 4 Teknik Perkapalan. | ||

| + | |||

| + | [[File:artha.jpg|200px|thumb|left|]] | ||

== Resume Pertemuan 1 (26/05/2023) == | == Resume Pertemuan 1 (26/05/2023) == | ||

| Line 8: | Line 10: | ||

== Design and Optimization of Pressurized Hydrogen Storage System == | == Design and Optimization of Pressurized Hydrogen Storage System == | ||

'''Objective''' | '''Objective''' | ||

| + | |||

Design and optimize pressurized hydrogen storage systems | Design and optimize pressurized hydrogen storage systems | ||

'''Specifications''' | '''Specifications''' | ||

| − | Capacity: | + | Capacity: 1 L |

| − | Pressure Level:8 bar | + | Pressure Level: 8 bar |

Cost: >500k | Cost: >500k | ||

| Line 21: | Line 24: | ||

In this project, I used the help of AI to guide me in designing and optimizing a hydrogen storage system. I used ChatGPT in helping me outline the process and here is its response. | In this project, I used the help of AI to guide me in designing and optimizing a hydrogen storage system. I used ChatGPT in helping me outline the process and here is its response. | ||

| + | |||

To design and optimize a pressurized hydrogen storage system with a capacity of 1 liter and a pressure level of 8 bar, we can consider the following factors: | To design and optimize a pressurized hydrogen storage system with a capacity of 1 liter and a pressure level of 8 bar, we can consider the following factors: | ||

| − | + | 1. Tank Material Selection: | |

| − | + | Choose a material with high strength-to-weight ratio and good hydrogen compatibility. Common options include high-strength steel alloys, carbon fiber composites, or aluminum alloys. Consider the material's weight, cost, and safety characteristics. | |

| + | |||

| + | 2. Tank Geometry: | ||

| + | Optimize the tank's geometry to maximize the storage capacity within the given volume of 1 liter. Consider cylindrical or spherical shapes as they offer efficient use of space and pressure containment. | ||

| + | |||

| + | 3. Tank Wall Thickness: | ||

| + | Determine the appropriate wall thickness to withstand the desired pressure level of 8 bar. The wall thickness will depend on the selected material and the tank's geometry. Perform stress analysis to ensure the tank's structural integrity. | ||

| + | |||

| + | 4. Safety Features: | ||

| + | Incorporate safety features like pressure relief valves, burst discs, and rupture disks to prevent over-pressurization and ensure the safe operation of the storage system. These features will release excess pressure in case of emergencies. | ||

| + | |||

| + | 5. Insulation: | ||

| + | Include effective insulation to minimize heat transfer and maintain hydrogen temperature. Insulation reduces energy losses and helps stabilize pressure within the tank. | ||

| + | |||

| + | 6. Valve and Fittings: | ||

| + | Select hydrogen-compatible valves and fittings capable of handling the desired pressure level. Ensure they provide efficient filling and emptying of hydrogen and allow for easy connection to other systems. | ||

| + | |||

| + | 7. Materials Compatibility: | ||

| + | Consider the compatibility of tank materials with hydrogen gas. Hydrogen can cause embrittlement in some materials, so it's crucial to choose materials that have been tested and proven to be compatible with hydrogen. | ||

| + | |||

| + | 8. Weight and Portability: | ||

| + | Optimize the design to minimize the overall weight of the storage system while maintaining safety and structural integrity. Consider the portability requirements if the system needs to be mobile. | ||

| + | |||

| + | 9. Cost Considerations: | ||

| + | Balance the cost of materials, manufacturing, and safety features while designing the system. Consider the trade-offs between different materials and manufacturing processes to achieve an optimal balance between cost and performance. | ||

| + | |||

| + | 10. Regulatory Compliance: | ||

| + | Ensure that the storage system design meets relevant safety standards and regulations for hydrogen storage. Consult local codes and guidelines to ensure compliance. | ||

| + | |||

| + | It's important to note that the design and optimization of a pressurized hydrogen storage system involve complex engineering considerations. Consulting with experts in hydrogen storage and working closely with experienced professionals in the field will help ensure a safe and efficient design. | ||

| + | |||

| + | |||

| + | == Final Report == | ||

| + | |||

| + | '''Material Selection''' | ||

| + | |||

| + | For this project im going to use Stainless Steel 304 otherwise known as UNS S30400 which is a part of the 300 Stainless Steel series, known for their durability, versatility, and corrosion resistance. | ||

| + | |||

| + | [[File:Stainless_steel.png]] | ||

| + | |||

| + | |||

| + | '''Tank Geometry''' | ||

| + | |||

| + | To maximize storage space, i will be using a cylindrical tank shape. Cylinders while saving a lot of space, can also spread the pressure evenly. Here is the calculations for the surface area of the tank. | ||

| + | |||

| + | import math | ||

| + | from scipy.optimize import minimize | ||

| + | |||

| + | def surface_area(r, h): | ||

| + | # Calculate the surface area of a cylinder | ||

| + | return 2 * math.pi * r * (r + h) | ||

| + | |||

| + | def volume_constraint(r, h): | ||

| + | # Calculate the volume of a cylinder | ||

| + | return math.pi * r**2 * h | ||

| + | |||

| + | def objective(x): | ||

| + | # Objective function to minimize: surface area | ||

| + | r, h = x | ||

| + | return surface_area(r, h) | ||

| + | |||

| + | def constraint(x): | ||

| + | # Constraint function: volume constraint | ||

| + | r, h = x | ||

| + | return volume_constraint(r, h) - 1.0 | ||

| + | |||

| + | # Initial guess for radius and height | ||

| + | x0 = [1.0, 1.0] | ||

| + | |||

| + | # Bounds for radius and height | ||

| + | bounds = [(0.0, None), (0.0, None)] | ||

| + | |||

| + | # Constraint definition | ||

| + | volume_constraint_definition = {'type': 'eq', 'fun': constraint} | ||

| + | |||

| + | # Solve the optimization problem | ||

| + | result = minimize(objective, x0, bounds=bounds, constraints=volume_constraint_definition) | ||

| + | |||

| + | # Extract the optimal values | ||

| + | optimal_radius, optimal_height = result.x | ||

| + | |||

| + | # Calculate the optimal surface area | ||

| + | optimal_surface_area = surface_area(optimal_radius, optimal_height) | ||

| + | |||

| + | # Print the results | ||

| + | print("Optimal Radius: {:.2f} cm".format(optimal_radius * 100)) | ||

| + | print("Optimal Height: {:.2f} cm".format(optimal_height * 100)) | ||

| + | print("Optimal Surface Area: {:.2f} cm^2".format(optimal_surface_area)) | ||

| + | |||

| + | |||

| + | With Results | ||

| + | |||

| + | Optimal Radius: 37.59 cm | ||

| + | Optimal Height: 225.27 cm | ||

| + | Optimal Surface Area: 6.21 cm^2 | ||

| + | |||

| + | |||

| + | '''Hoop Stress''' | ||

| + | |||

| + | In calculating the thickness of the tank, first we need to find the hoop stress. Hoop stress, also known as circumferential stress, is a type of mechanical stress that occurs in a cylindrical or spherical object when it is subjected to internal or external pressure. It is named "hoop stress" because it primarily acts tangentially around the circumference of the object, like a hoop. | ||

| + | |||

| + | In a cylindrical object, such as a pipe or a pressure vessel, the hoop stress is responsible for resisting the tendency of the object to burst or rupture due to the internal pressure. When the pressure inside the cylinder increases, the hoop stress also increases. Here are the calculations for hoop stress. | ||

| + | |||

| + | def calculate_hoop_stress(pressure, radius, thickness): | ||

| + | hoop_stress = (pressure * radius) / thickness | ||

| + | return hoop_stress | ||

| + | |||

| + | # Input values | ||

| + | pressure = 8 # bar | ||

| + | radius = 37 / 100 # converting cm to meters | ||

| + | height = 225 / 100 # converting cm to meters | ||

| + | |||

| + | # Assume a wall thickness (e.g., 1 cm) | ||

| + | thickness = 1 / 100 # converting cm to meters | ||

| + | |||

| + | # Calculate hoop stress | ||

| + | hoop_stress = calculate_hoop_stress(pressure, radius, thickness) | ||

| + | |||

| + | # Print the result | ||

| + | print("Hoop Stress: {:.2f} Pa".format(hoop_stress)) | ||

| + | |||

| + | Resulting in hoop stress with value of | ||

| + | |||

| + | Hoop Stress: 296.00 Pa | ||

| + | |||

| + | |||

| + | '''Tank Thickness''' | ||

| + | |||

| + | After calculating the hoop stress, we can find the thickness of the tank. To caclulate the thickness of the tank, we will be using this code | ||

| + | |||

| + | def calculate_thickness(radius, pressure, yield_strength, safety_factor): | ||

| + | # Calculate the required thickness based on the pressure, radius, yield strength, and safety factor | ||

| + | thickness = (pressure * radius) / (2 * yield_strength * safety_factor) | ||

| + | |||

| + | return thickness | ||

| + | |||

| + | # Given the radius of the cylindrical structure | ||

| + | radius = 37 # cm | ||

| + | |||

| + | # Given the internal pressure in bars | ||

| + | pressure = 8 # bar | ||

| + | |||

| + | # Given the yield strength of stainless steel 304 in pascal (Pa) | ||

| + | yield_strength = 275e6 # Pa | ||

| + | |||

| + | # Given the safety factor for the design | ||

| + | safety_factor = 1.5 | ||

| + | |||

| + | # Convert pressure to pascal (Pa) | ||

| + | pressure_pa = pressure * 1e5 | ||

| + | |||

| + | # Calculate the thickness | ||

| + | thickness = calculate_thickness(radius, pressure_pa, yield_strength, safety_factor) | ||

| + | |||

| + | # Print the thickness | ||

| + | print("Thickness:", thickness, "m") | ||

| + | |||

| + | Resulting in | ||

| + | |||

| + | Thickness: 0.003587878787878788 m | ||

| + | |||

| + | |||

| + | '''Cost''' | ||

| − | + | After calculating the spesifications of our tank, we need to research for the cost of materials used in our tank which in our case is 304 Stainless Steel. In the current marketplace, the price for a sheet of 304 Stainless Steel with 5 mm and area of 10 cm X 10cm is Rp. 133.000,00. Adding production costs like welding and other costs we can estimate the price of 1 hydrogen tank to be under Rp.400.000,00. | |

| − | |||

| − | |||

| − | |||

| − | ''' | + | '''Conclusion''' |

| − | |||

| − | + | After researching, designing, and optimizing storage for hydrogen, we can come to the conclusion that there are multiple approaches that we can do to optimize and create a more efficient solution. This gives insight to how we can optimize a lot more systems in our daily lives to make engineering more efficient | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == Presentation of my Hydrogen Storage System Design and Optimization== | |

| − | |||

| − | + | Here is the link of my presentation for my project on designing and optimizing hydrogen storage systems | |

| − | |||

| − | + | [https://www.youtube.com/watch?v=hHdlucwduHQ] | |

Latest revision as of 22:03, 15 June 2023

Contents

Introduction

Nama saya Artha Danaraja Dewantoro dengan NPM 2106731106, lahir pada tanggal 11 April 2003 di Jakarta Selatan. Saya berdomisili di Bintaro, Tangerang Selatan dengan keluarga saya. Saya mahasiswa semester 4 Teknik Perkapalan.

Resume Pertemuan 1 (26/05/2023)

Pada pertemuan pertama Metode Numerik yang diampu Pak DAI, kita belajar tentang conscioussness in learning. Consciousness atau kesadaran merupakan kemampuan individu untuk menyadari dan mengalami dunia di sekitarnya. Kali ini, Pak DAI mengimplementasikan consciouscness kedalam penyelesaian operasi matematika. Kita selalu berasumsi bahwa matematika adalah sesuatu yang eksak, namun ada kasus dimana hasil operasi tersebut tidak pasti. Disitulah kesadaran kita sebagai manusia digunakan, dimana kita harus ingat hanya Tuhan yang memiliki kebenaran mutlak. Kita juga ditugaskan untuk mendesain dan optimasi penyimpanan hydrogen bertekanan dengan kapasitas 1 L dan tekanan 8 bar.

Design and Optimization of Pressurized Hydrogen Storage System

Objective

Design and optimize pressurized hydrogen storage systems

Specifications

Capacity: 1 L

Pressure Level: 8 bar

Cost: >500k

Week 1

In this project, I used the help of AI to guide me in designing and optimizing a hydrogen storage system. I used ChatGPT in helping me outline the process and here is its response.

To design and optimize a pressurized hydrogen storage system with a capacity of 1 liter and a pressure level of 8 bar, we can consider the following factors:

1. Tank Material Selection:

Choose a material with high strength-to-weight ratio and good hydrogen compatibility. Common options include high-strength steel alloys, carbon fiber composites, or aluminum alloys. Consider the material's weight, cost, and safety characteristics.

2. Tank Geometry:

Optimize the tank's geometry to maximize the storage capacity within the given volume of 1 liter. Consider cylindrical or spherical shapes as they offer efficient use of space and pressure containment.

3. Tank Wall Thickness:

Determine the appropriate wall thickness to withstand the desired pressure level of 8 bar. The wall thickness will depend on the selected material and the tank's geometry. Perform stress analysis to ensure the tank's structural integrity.

4. Safety Features:

Incorporate safety features like pressure relief valves, burst discs, and rupture disks to prevent over-pressurization and ensure the safe operation of the storage system. These features will release excess pressure in case of emergencies.

5. Insulation:

Include effective insulation to minimize heat transfer and maintain hydrogen temperature. Insulation reduces energy losses and helps stabilize pressure within the tank.

6. Valve and Fittings:

Select hydrogen-compatible valves and fittings capable of handling the desired pressure level. Ensure they provide efficient filling and emptying of hydrogen and allow for easy connection to other systems.

7. Materials Compatibility:

Consider the compatibility of tank materials with hydrogen gas. Hydrogen can cause embrittlement in some materials, so it's crucial to choose materials that have been tested and proven to be compatible with hydrogen.

8. Weight and Portability:

Optimize the design to minimize the overall weight of the storage system while maintaining safety and structural integrity. Consider the portability requirements if the system needs to be mobile.

9. Cost Considerations:

Balance the cost of materials, manufacturing, and safety features while designing the system. Consider the trade-offs between different materials and manufacturing processes to achieve an optimal balance between cost and performance.

10. Regulatory Compliance:

Ensure that the storage system design meets relevant safety standards and regulations for hydrogen storage. Consult local codes and guidelines to ensure compliance.

It's important to note that the design and optimization of a pressurized hydrogen storage system involve complex engineering considerations. Consulting with experts in hydrogen storage and working closely with experienced professionals in the field will help ensure a safe and efficient design.

Final Report

Material Selection

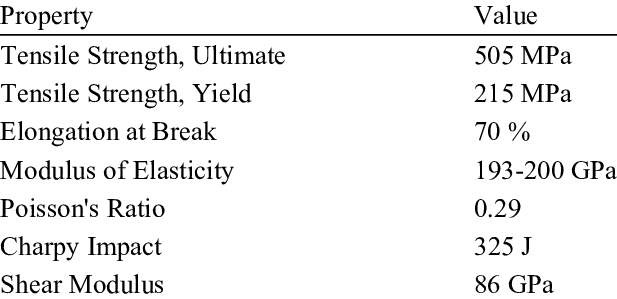

For this project im going to use Stainless Steel 304 otherwise known as UNS S30400 which is a part of the 300 Stainless Steel series, known for their durability, versatility, and corrosion resistance.

Tank Geometry

To maximize storage space, i will be using a cylindrical tank shape. Cylinders while saving a lot of space, can also spread the pressure evenly. Here is the calculations for the surface area of the tank.

import math from scipy.optimize import minimize

def surface_area(r, h):

# Calculate the surface area of a cylinder return 2 * math.pi * r * (r + h)

def volume_constraint(r, h):

# Calculate the volume of a cylinder return math.pi * r**2 * h

def objective(x):

# Objective function to minimize: surface area r, h = x return surface_area(r, h)

def constraint(x):

# Constraint function: volume constraint r, h = x return volume_constraint(r, h) - 1.0

- Initial guess for radius and height

x0 = [1.0, 1.0]

- Bounds for radius and height

bounds = [(0.0, None), (0.0, None)]

- Constraint definition

volume_constraint_definition = {'type': 'eq', 'fun': constraint}

- Solve the optimization problem

result = minimize(objective, x0, bounds=bounds, constraints=volume_constraint_definition)

- Extract the optimal values

optimal_radius, optimal_height = result.x

- Calculate the optimal surface area

optimal_surface_area = surface_area(optimal_radius, optimal_height)

- Print the results

print("Optimal Radius: {:.2f} cm".format(optimal_radius * 100)) print("Optimal Height: {:.2f} cm".format(optimal_height * 100)) print("Optimal Surface Area: {:.2f} cm^2".format(optimal_surface_area))

With Results

Optimal Radius: 37.59 cm Optimal Height: 225.27 cm Optimal Surface Area: 6.21 cm^2

Hoop Stress

In calculating the thickness of the tank, first we need to find the hoop stress. Hoop stress, also known as circumferential stress, is a type of mechanical stress that occurs in a cylindrical or spherical object when it is subjected to internal or external pressure. It is named "hoop stress" because it primarily acts tangentially around the circumference of the object, like a hoop.

In a cylindrical object, such as a pipe or a pressure vessel, the hoop stress is responsible for resisting the tendency of the object to burst or rupture due to the internal pressure. When the pressure inside the cylinder increases, the hoop stress also increases. Here are the calculations for hoop stress.

def calculate_hoop_stress(pressure, radius, thickness):

hoop_stress = (pressure * radius) / thickness return hoop_stress

- Input values

pressure = 8 # bar radius = 37 / 100 # converting cm to meters height = 225 / 100 # converting cm to meters

- Assume a wall thickness (e.g., 1 cm)

thickness = 1 / 100 # converting cm to meters

- Calculate hoop stress

hoop_stress = calculate_hoop_stress(pressure, radius, thickness)

- Print the result

print("Hoop Stress: {:.2f} Pa".format(hoop_stress))

Resulting in hoop stress with value of

Hoop Stress: 296.00 Pa

Tank Thickness

After calculating the hoop stress, we can find the thickness of the tank. To caclulate the thickness of the tank, we will be using this code

def calculate_thickness(radius, pressure, yield_strength, safety_factor):

# Calculate the required thickness based on the pressure, radius, yield strength, and safety factor thickness = (pressure * radius) / (2 * yield_strength * safety_factor)

return thickness

- Given the radius of the cylindrical structure

radius = 37 # cm

- Given the internal pressure in bars

pressure = 8 # bar

- Given the yield strength of stainless steel 304 in pascal (Pa)

yield_strength = 275e6 # Pa

- Given the safety factor for the design

safety_factor = 1.5

- Convert pressure to pascal (Pa)

pressure_pa = pressure * 1e5

- Calculate the thickness

thickness = calculate_thickness(radius, pressure_pa, yield_strength, safety_factor)

- Print the thickness

print("Thickness:", thickness, "m")

Resulting in

Thickness: 0.003587878787878788 m

Cost

After calculating the spesifications of our tank, we need to research for the cost of materials used in our tank which in our case is 304 Stainless Steel. In the current marketplace, the price for a sheet of 304 Stainless Steel with 5 mm and area of 10 cm X 10cm is Rp. 133.000,00. Adding production costs like welding and other costs we can estimate the price of 1 hydrogen tank to be under Rp.400.000,00.

Conclusion

After researching, designing, and optimizing storage for hydrogen, we can come to the conclusion that there are multiple approaches that we can do to optimize and create a more efficient solution. This gives insight to how we can optimize a lot more systems in our daily lives to make engineering more efficient

Presentation of my Hydrogen Storage System Design and Optimization

Here is the link of my presentation for my project on designing and optimizing hydrogen storage systems