Difference between revisions of "Ridwan Sholehan"

(→Study Case: Optimization Hydrogen Storage) |

(→INTRODUCTION) |

||

| Line 9: | Line 9: | ||

'''Motto Hidup:''' | '''Motto Hidup:''' | ||

''"Jangan Terlalu Terpaku Akan Suatu Penyesalan, Yang Terpenting Adalah Bagaimana Langkah Untuk Membangun Masa Depan Yang Lebih Baik"'' | ''"Jangan Terlalu Terpaku Akan Suatu Penyesalan, Yang Terpenting Adalah Bagaimana Langkah Untuk Membangun Masa Depan Yang Lebih Baik"'' | ||

| + | |||

| + | |||

| + | ==Brief introduction to the advantages of hydrogen as a fuel== | ||

== Study Case: Optimization Hydrogen Storage == | == Study Case: Optimization Hydrogen Storage == | ||

Revision as of 00:07, 12 June 2023

Contents

INTRODUCTION

Nama :Ridwan Sholehan

NPM :2206100312

Motto Hidup:

"Jangan Terlalu Terpaku Akan Suatu Penyesalan, Yang Terpenting Adalah Bagaimana Langkah Untuk Membangun Masa Depan Yang Lebih Baik"

Brief introduction to the advantages of hydrogen as a fuel

Study Case: Optimization Hydrogen Storage

Hydrogen Storage Requirement

In this case we want to build a storage with:

1. Capacity : 1 Liter.

2. Pressure : 8 Bar.

3. Budget : Rp. 500.000,-

4. Can be installed in a vehicle such as a motorcycle.

Material Classification

Hydrogen storage materials can be of different types:

1. dissociative material in which molecular hydrogen is dissociated into hydrogen atoms, which occupy interstitial sites.

2. material with chemically bound hydrogen.

3. materials that adsorb molecular hydrogen.

Hydrogen storage in solid form can be briefly classified into the following categories:

1. metal hydrides

2. light metal-based hydrides

3. chemical hydrides (complex hydrides)

4. nanostructured materials (adsorption of molecular hydrogen)

Refers to the type above. There is a material that can be used to build storage. Hydrogen Magnesium Hydride (MgH2) storage material by inserting a double catalyst, namely Iron Oxide (Fe2O3) and Silicon Carbide (SiC) each of 5wt% as an effort to improve the absorption properties and reaction kinetics of magnesium-based hydrogen storage materials.

Design of Storage Tank

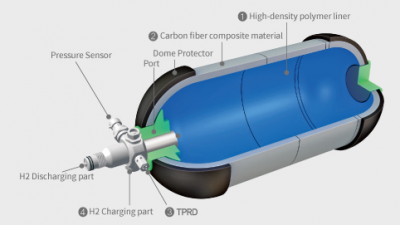

This is a reference to the design of the storage hydrogen Tank. this design has several advantages because it will be installed in a vehicle it has to be lightweight, high durability, and efficient to be used in the vehicle.

Calculation of Hydrogen Storage

Specification:

1. Capacity --> Volume : 1 liter = 0.001 m^3

2. Because this storage will be installed in vehicles, which means having limited space. we can assume for :

R : 10 cm = 0.1 m

r : 5 cm = 0.05 m

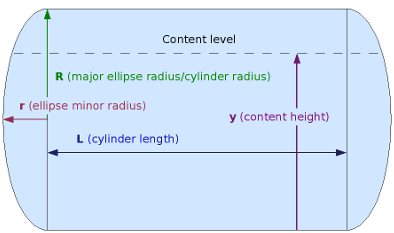

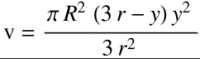

For the bottom and top of a vertical tank, for provided values for R and r as described above, and content bisector y, with numerical ranges of 0 <= y <= r, and L+r <= y <= L+2r (with some technical adjustments of the range of y and of the resulting volume for the top ellipse):

And for the cylinder in the middle, for a provided value of R (cylinder radius) and with the numerical range of r <= y <= L+r

So we can get L from the equation above:

y = 0.081 m

Tank Testing and Safety Consideration

In accordance with ISO/TS 15869 (revised):

1. Burst test: the pressure at which the tank bursts, typically more than 2× the working pressure.

2. Proof pressure: the pressure at which the test will be executed, typically above the working pressure.

3. Leak test or permeation test,[9] in NmL/hr/L (Normal liter of H2/time in hr/volume of the tank.)

4. Fatigue test, typically several thousand cycles of charging/emptying.

5. Bonfire test where the tank is exposed to an open fire.

6. Bullet test where live ammunition is fired at the tank.

Design Calculation of Hydrogen Storage Tank

1. Choose Material

For Material, we can use composite material such as steel aluminum, because is prepared for fabrication. This material can be easy for manufacturing processes such as cutting, shaping, or molding the material into the desired form for the tank components.

2. Spesification For Tank

Pressure Tank : 8 bar Volume Tank : 1 liter : 0.001 m^3 Budget : 500.000,-

3. Design Tank

1. Design Tank

Assume diameter for tank is 10 cm : 0.1 m

V = πr^2h 0.001 = π . (0.05^2) . h h = 0.127 m or can we round it up 0.15 m

2. Permissible Pressure (using safety factor)

P = 8 bar = 8 x 10^5 Pa

Permissible Pressure = 8 x 10^5 Pa x 3 = 24 x 10^5 Pa

3. Standard From ASME VIII

Joint efficiency (E) : 0.85 MAWS (SS-304 Seamless Pipe) : 30000 psi OD : 100 mm OR : 50 mm Corrosion Allowance (CA) : 0.25 mm Thickness (ta) : 1.27 mm Thickness (t) = (ta-CA) : 1.02 mm

4. Manufacturing Process

Because that shape of the material is plat, we can use manufacturing processes is:

1. Cutting

2. Bending

3. Forming

4. Welding

5. Tank Testing and Safety Consideration

In accordance with ISO/TS 15869 (revised):

1. Burst test: the pressure at which the tank bursts, typically more than 2× the working pressure.

2. Proof pressure: the pressure at which the test will be executed, typically above the working pressure.

3. Leak test or permeation test,[9] in NmL/hr/L (Normal liter of H2/time in hr/volume of the tank.)

4. Fatigue test, typically several thousand cycles of charging/emptying.

5. Bonfire test where the tank is exposed to an open fire.

6. Bullet test where live ammunition is fired at the tank.