Difference between revisions of "Nabila Khoirun Nisa"

(→Perhitungan Hydrogen Storage) |

(→Perhitungan Hydrogen Storage) |

||

| Line 71: | Line 71: | ||

== Perhitungan Hydrogen Storage == | == Perhitungan Hydrogen Storage == | ||

| + | |||

| + | '''Menghitung Ketebalan Bahan''' | ||

def calculate_optimized_thickness(volume, pressure): | def calculate_optimized_thickness(volume, pressure): | ||

| − | + | # Stainless Steel properties | |

| − | + | yield_strength = 205e6 # Yield strength of the stainless steel in Pascals | |

| − | + | safety_factor = 3 # Desired safety factor | |

| − | + | # Conversion factors | |

| − | + | bar_to_pa = 1e5 # Bar to Pascal conversion factor | |

| + | |||

| + | # Convert pressure to Pascal | ||

| + | pressure_pa = pressure * bar_to_pa | ||

| − | + | # Calculate the radius of the cylinder using the given volume | |

| − | + | radius = (3 * volume / (4 * math.pi))**(1/3) | |

| − | + | # Calculate the hoop stress | |

| − | + | hoop_stress = pressure_pa * radius / 2 | |

| − | + | # Calculate the required thickness | |

| − | + | thickness = hoop_stress * safety_factor / yield_strength | |

| − | + | # Convert thickness to millimeters | |

| − | + | thickness_mm = thickness * 1000 | |

| − | + | return thickness_mm | |

| − | |||

| − | |||

| − | |||

| − | + | # Input parameters | |

| − | + | volume = 1 # 1-liter capacity | |

| − | + | pressure = 8 # 8 bar pressure | |

# Calculate the optimized thickness | # Calculate the optimized thickness | ||

| Line 106: | Line 108: | ||

print(f"The optimized thickness of the stainless steel hydrogen storage vessel is {optimized_thickness:.2f} mm.") | print(f"The optimized thickness of the stainless steel hydrogen storage vessel is {optimized_thickness:.2f} mm.") | ||

| − | Maka, diperoleh ketebalan Hydrogen Storage adalah 3,63 mm | + | Maka, diperoleh ketebalan bahan stainless steel untuk Hydrogen Storage adalah 3,63 mm |

| + | |||

| + | '''Menghitung Luas Tabung''' | ||

| + | |||

| + | import math | ||

| + | |||

| + | def calculate_surface_area(radius, height): | ||

| + | # Calculate the surface area of the tube | ||

| + | base_area = math.pi * radius**2 | ||

| + | lateral_area = 2 * math.pi * radius * height | ||

| + | surface_area = 2 * base_area + lateral_area | ||

| + | |||

| + | return surface_area | ||

| + | |||

| + | def find_optimal_dimensions(volume, pressure, tensile_strength): | ||

| + | # Convert volume from mL to cm^3 | ||

| + | volume_cm3 = volume | ||

| + | |||

| + | # Convert pressure from bar to Pascal | ||

| + | pressure_pa = pressure * 100000 | ||

| + | |||

| + | # Initialize variables for optimal dimensions | ||

| + | optimal_radius = None | ||

| + | optimal_height = None | ||

| + | min_surface_area = float('inf') | ||

| + | |||

| + | # Iterate over possible radius values | ||

| + | for radius in range(1, int(math.sqrt(volume_cm3 / math.pi)) + 1): | ||

| + | # Calculate the corresponding height for the given volume and radius | ||

| + | height = volume_cm3 / (math.pi * radius**2) | ||

| + | |||

| + | # Calculate the surface area for the current dimensions | ||

| + | surface_area = calculate_surface_area(radius, height) | ||

| + | |||

| + | # Check if the current surface area is the lowest found so far | ||

| + | if surface_area < min_surface_area: | ||

| + | min_surface_area = surface_area | ||

| + | optimal_radius = radius | ||

| + | optimal_height = height | ||

| + | |||

| + | # Convert optimal radius to centimeters | ||

| + | optimal_radius_cm = optimal_radius | ||

| + | |||

| + | return optimal_radius_cm, optimal_height | ||

| + | |||

| + | # Define the input parameters | ||

| + | volume = 1000 # 1 liter = 1000 mL | ||

| + | pressure = 8 # bar | ||

| + | tensile_strength = 515 # MPa | ||

| + | |||

| + | # Find the optimal dimensions | ||

| + | optimal_radius_cm, optimal_height = find_optimal_dimensions(volume, pressure, tensile_strength) | ||

| + | |||

| + | # Display the results | ||

| + | print(f"Dimensi yang menghasilkan luas permukaan terendah untuk tabung 1 liter dengan tekanan 8 bar:") | ||

| + | print(f"Radius: {optimal_radius_cm} cm") | ||

| + | print(f"Tinggi: {optimal_height} cm") | ||

| + | |||

| + | The optimized height of the aluminum alloy hydrogen storage tank is 225.68 mm. | ||

Revision as of 10:55, 9 June 2023

Contents

Introduction

Perkenalkan saya Nabila Khoirun Nisa, lahir di Bogor, 27 Agustus 2003. Saya berdomisili di Kota Depok.

Resume Kuliah Pertemuan 26/05/2023

Pada pertemuan ini, dijelaskan tentang penjelasan metode numerik dan penerapannya yang berhubungan dengan kehidupan. Lalu diberikan soal yaitu berapakah nilai X^2-1/X-1 jika X=1, penyelesaian untuk soal ini ada dua cara. Cara pertama jika langsung memasukin nilai x=1 kedalam persamaan tersebut maka akan didapatkan nilai 0/0 (tidak terdefinisi), pembagian 0/0 didalam matematika itu menimbulkan ambiguitas karena hasilnya tidak eksak dan tidak mempunyai nilai numerik yang tepat, mungkin bisa menggunakan bahasa pemrograman untuk mendapatkan nilai yang mendekati 0 tapi nilai tersebut tetap tidak eksak. Cara kedua dengan menjabarkan persamaannya tersebut menjadi (x+1)(x-1)/(x-1) maka akan didapatkan nilai 2. Namun kedua jawaban ini tetaplah tidak eksak karena yang eksak di dunia ini hanyalah Tuhan yang Maha Esa.

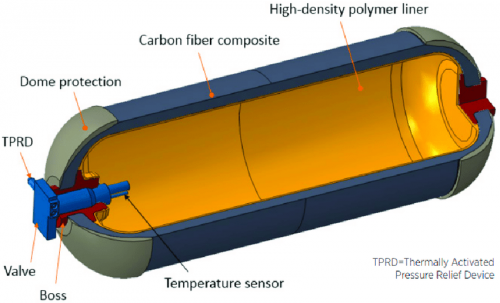

Design & Optimization of Pressurized Hydrogen Storage

Designing and optimizing a pressurized hydrogen storage system with a capacity of 1 liter and a pressure level of 8 bar while keeping the cost below Rp 500,000 requires careful consideration of various factors. On this occasion, I am using ChatGPT to answer the question. Here's a high-level approach you can follow:

• Tank Selection

Choose a suitable tank material and design that can withstand the required pressure and store 1 liter of hydrogen. Common materials for hydrogen storage tanks include carbon fiber composites and certain types of steel.

• Tank Sizing

Determine the optimal tank size based on the desired capacity of 1 liter and pressure level of 8 bar. Consider factors such as the hydrogen's density, temperature effects, and safety margins.

• Safety Measures

Ensure that the storage system incorporates safety features to prevent leakage, rupture, and other hazards. This may include pressure relief valves, burst discs, and proper sealing mechanisms.

• Material Cost Optimization

Explore various materials and manufacturing techniques to reduce the cost of the storage system while maintaining safety and performance requirements. This may involve analyzing different suppliers, considering alternative materials, or optimizing the manufacturing process.

• Manufacturing Process

Optimize the production process to minimize costs. This could involve techniques such as automated manufacturing, bulk purchasing of components, or leveraging economies of scale.

• System Integration

Consider the overall integration of the storage system within the larger hydrogen infrastructure. This includes connections to hydrogen production and distribution systems, as well as any necessary safety interlocks or controls.

• Cost Analysis

Conduct a comprehensive cost analysis, factoring in material costs, manufacturing costs, quality control, safety measures, and any other associated expenses. Ensure that the total cost remains below Rp 500,000.

• Performance Optimization

Assess the overall performance of the storage system, including factors such as efficiency, weight, and size. Look for opportunities to optimize the design to enhance performance while keeping costs within budget.

It's important to note that the cost of hydrogen storage systems can vary significantly depending on factors such as local market conditions, manufacturing capabilities, and specific design requirements. The provided budget constraint might be challenging to achieve, so additional research and cost analysis would be necessary to identify specific solutions that meet your requirements.

Final Report Design Hydrogen Storage

Hidrogen dianggap sebagai salah satu solusi potensial untuk mengurangi emisi gas rumah kaca dan mengatasi ketergantungan terhadap bahan bakar fosil. Namun, penyimpanan hidrogen merupakan tantangan teknis karena sifatnya yang memiliki kepadatan energi yang tinggi tetapi memiliki massa jenis yang rendah. Hidrogen gas biasanya harus disimpan pada tekanan yang tinggi atau dalam bentuk cair pada suhu sangat rendah untuk mencapai kepadatan energi yang memadai. Oleh karena itu, pengembangan tangki penyimpanan hidrogen yang efisien, aman, dan terjangkau sangat penting.

Pemilihan Material

Terdapat beberapa material yang umum digunakan untuk penyimpanan hidrogen dalam tangki. Beberapa diantaranya yaitu:

- Baja Karbon (Carbon Steel): Baja karbon adalah material yang kuat dan tahan korosi, sehingga sering digunakan untuk tangki penyimpanan hidrogen. Namun, baja karbon memiliki kecenderungan terhadap fragilitas yang disebabkan oleh hidrogen, terutama pada tekanan tinggi dan suhu rendah. - Baja Tahan Karat (Stainless Steel): Baja tahan karat seperti 316 stainless steel atau 304 stainless steel sering digunakan untuk tangki penyimpanan hidrogen. Baja tahan karat memiliki ketahanan yang lebih baik terhadap korosi oleh hidrogen. - Aluminium: Aluminium memiliki kepadatan yang rendah dan tahan korosi, sehingga juga merupakan pilihan yang populer untuk penyimpanan hidrogen. Namun, aluminium cenderung memiliki kebocoran hidrogen yang lebih tinggi dibandingkan dengan baja. - Komposit Serat Karbon (Carbon Fiber Composites): Komposit serat karbon memiliki kekuatan yang tinggi dan kepadatan yang rendah, sehingga menjadi alternatif yang menarik untuk penyimpanan hidrogen. Komposit serat karbon dapat mengatasi beberapa masalah fragilitas yang terkait dengan baja karbon. - Polimer Kuat (High-Strength Polymers): Beberapa polimer kuat seperti polietilena berdensitas tinggi (HDPE) dan polieterketon (PEK) juga digunakan dalam tangki penyimpanan hidrogen. Polimer ini memiliki kekuatan yang cukup tinggi dan tahan terhadap korosi hidrogen.

Pemilihan material untuk tangki penyimpanan hidrogen harus mempertimbangkan faktor seperti kekuatan, ketahanan korosi, ketahanan terhadap fragilitas hidrogen, dan kebutuhan lainnya tergantung pada aplikasi spesifik. Selain itu, penting untuk mematuhi regulasi keselamatan yang berlaku dalam pemilihan dan penggunaan material tersebut. Material yang saya pilih untuk Hydrogen Storage adalah 316 stainless steel.

Spesifikasi Hydrogen Storage

Volume Tank: 1 Liter Tekanan: 8 bar Anggaran maksimal: Rp 500.000 Material: 316 stainless steel

Perhitungan Hydrogen Storage

Menghitung Ketebalan Bahan

def calculate_optimized_thickness(volume, pressure):

# Stainless Steel properties

yield_strength = 205e6 # Yield strength of the stainless steel in Pascals

safety_factor = 3 # Desired safety factor

# Conversion factors

bar_to_pa = 1e5 # Bar to Pascal conversion factor

# Convert pressure to Pascal

pressure_pa = pressure * bar_to_pa

# Calculate the radius of the cylinder using the given volume

radius = (3 * volume / (4 * math.pi))**(1/3)

# Calculate the hoop stress

hoop_stress = pressure_pa * radius / 2

# Calculate the required thickness

thickness = hoop_stress * safety_factor / yield_strength

# Convert thickness to millimeters

thickness_mm = thickness * 1000

return thickness_mm

# Input parameters

volume = 1 # 1-liter capacity

pressure = 8 # 8 bar pressure

# Calculate the optimized thickness optimized_thickness = calculate_optimized_thickness(volume, pressure)

print(f"The optimized thickness of the stainless steel hydrogen storage vessel is {optimized_thickness:.2f} mm.")

Maka, diperoleh ketebalan bahan stainless steel untuk Hydrogen Storage adalah 3,63 mm

Menghitung Luas Tabung

import math

def calculate_surface_area(radius, height):

# Calculate the surface area of the tube base_area = math.pi * radius**2 lateral_area = 2 * math.pi * radius * height surface_area = 2 * base_area + lateral_area

return surface_area

def find_optimal_dimensions(volume, pressure, tensile_strength):

# Convert volume from mL to cm^3 volume_cm3 = volume

# Convert pressure from bar to Pascal pressure_pa = pressure * 100000

# Initialize variables for optimal dimensions

optimal_radius = None

optimal_height = None

min_surface_area = float('inf')

# Iterate over possible radius values

for radius in range(1, int(math.sqrt(volume_cm3 / math.pi)) + 1):

# Calculate the corresponding height for the given volume and radius

height = volume_cm3 / (math.pi * radius**2)

# Calculate the surface area for the current dimensions

surface_area = calculate_surface_area(radius, height)

# Check if the current surface area is the lowest found so far

if surface_area < min_surface_area:

min_surface_area = surface_area

optimal_radius = radius

optimal_height = height

# Convert optimal radius to centimeters optimal_radius_cm = optimal_radius

return optimal_radius_cm, optimal_height

- Define the input parameters

volume = 1000 # 1 liter = 1000 mL pressure = 8 # bar tensile_strength = 515 # MPa

- Find the optimal dimensions

optimal_radius_cm, optimal_height = find_optimal_dimensions(volume, pressure, tensile_strength)

- Display the results

print(f"Dimensi yang menghasilkan luas permukaan terendah untuk tabung 1 liter dengan tekanan 8 bar:") print(f"Radius: {optimal_radius_cm} cm") print(f"Tinggi: {optimal_height} cm")

The optimized height of the aluminum alloy hydrogen storage tank is 225.68 mm.