Difference between revisions of "Faizal Rikaz Al Muntaqo"

Rikazfaizal (talk | contribs) (→Pertemuan 6 (23/12/20)) |

Rikazfaizal (talk | contribs) (→Ujian Akhir Semester/ UAS (13/01/21)) |

||

| (30 intermediate revisions by the same user not shown) | |||

| Line 499: | Line 499: | ||

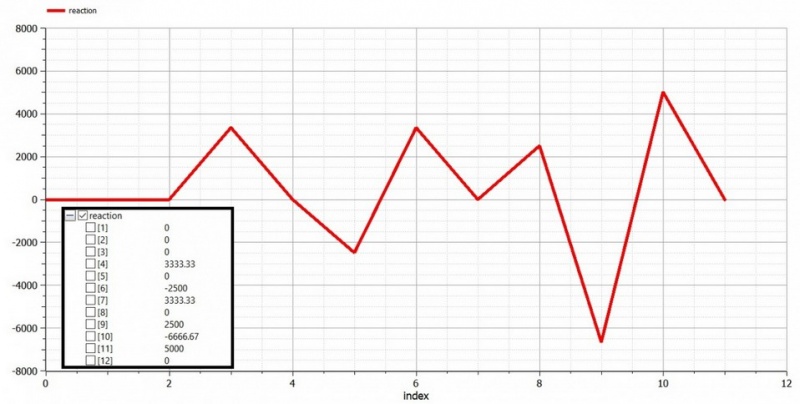

Pada pertemuan ke 6 ini kami diberi sebuah tugas besar yang dimana mahasiswa diharuskan mendesign suatu rangka dengan hasil yang terbaik namun juga memerhatikan cost agar mndapat harga yang relatif murah pula. Selain mempertimbangkan biaya serta material, area cross section truss pun juga ikut dipertimbangkan. | Pada pertemuan ke 6 ini kami diberi sebuah tugas besar yang dimana mahasiswa diharuskan mendesign suatu rangka dengan hasil yang terbaik namun juga memerhatikan cost agar mndapat harga yang relatif murah pula. Selain mempertimbangkan biaya serta material, area cross section truss pun juga ikut dipertimbangkan. | ||

| − | [[File:Soal Tubes Metnum Faizal Rikaz A_1.jpg| | + | [[File:Soal Tubes Metnum Faizal Rikaz A_1.jpg|450px]] [[File:Soal Tubes Metnum Faizal Rikaz A_2.jpg|200px]] |

'''Pendefinisian''' | '''Pendefinisian''' | ||

| Line 505: | Line 505: | ||

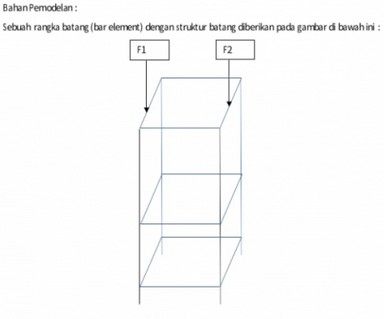

Berikut merupakan pendefinisian node dan elemen pada struktur batang. | Berikut merupakan pendefinisian node dan elemen pada struktur batang. | ||

| − | [[File:Soal Tubes Metnum Faizal Rikaz A_3.jpg|400px]] | + | [[File:Soal Tubes Metnum Faizal Rikaz A_3.jpg|400px]] |

'''Asumsi dan Constraint pada problem''' | '''Asumsi dan Constraint pada problem''' | ||

Asumsi | Asumsi | ||

| − | *Material | + | *Material |

| − | *Luas permukaan truss | + | *Luas permukaan truss |

| − | *Tidak adanya bending | + | *Tidak adanya bending |

| − | *Beban terdistribusi di node - node | + | *Beban terdistribusi di node - node |

| − | *Batas displacement 0,001m sebelum buckling | + | *Batas displacement 0,001m sebelum buckling |

| − | *Nilai safety factor 2 | + | *Nilai safety factor 2 |

Constraint: | Constraint: | ||

| − | *Node 1, 2, 3, dan 4 fixed. | + | *Node 1, 2, 3, dan 4 fixed. |

| − | *Beban F1 dan F2 terdistribusi ke node sekitarnya | + | *Beban F1 dan F2 terdistribusi ke node sekitarnya |

| − | *Node 13 & 16 = 1000N | + | *Node 13 & 16 = 1000N |

| − | *Node 14 & 15 = 500N | + | *Node 14 & 15 = 500N |

'''Data yang digunakan''' | '''Data yang digunakan''' | ||

| Line 527: | Line 527: | ||

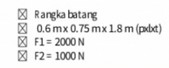

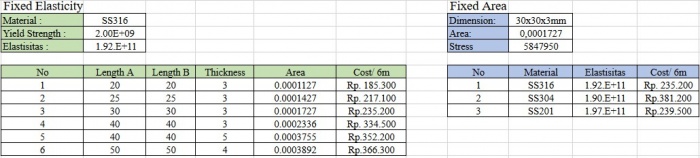

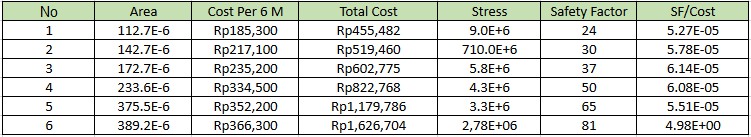

Berikut merupakan dua metode pendekatan yang digunakan dalam pencarian dimensi area dan material teroptimal dalam pembentukan rangka. | Berikut merupakan dua metode pendekatan yang digunakan dalam pencarian dimensi area dan material teroptimal dalam pembentukan rangka. | ||

| − | [[File:Tubes Metnum Faizal Rikaz A_1.jpg|700px]] | + | [[File:Tubes Metnum Faizal Rikaz A_1.jpg|700px]] |

'''Permodelan Numerik''' | '''Permodelan Numerik''' | ||

| Line 803: | Line 803: | ||

end Opt_Gold; | end Opt_Gold; | ||

| + | |||

| + | |||

| + | '''Hasil Perhitungan''' | ||

| + | |||

| + | *Fixed Elasticity | ||

| + | |||

| + | Berikut merupakan hasil perhitungan dengan fixed elasticity | ||

| + | |||

| + | Dan berikut merupakan grafik yang diperoleh dengan menggunakan metode Curve Fitting | ||

| + | |||

| + | [[File:Tubes Metnum Faizal Rikaz A_3 Fixed Elasticity.jpg|800px]] | ||

| + | |||

| + | [[File:Tubes Metnum Faizal Rikaz A_5 Fixed Elasticity.jpg|300px]] | ||

| + | |||

| + | Dari hasil diatas dapat dilihat bahwa hasil yang paling optimum adalah SS316 dengan dimensi 30x30x3mm | ||

| + | |||

| + | |||

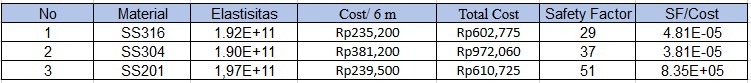

| + | *Fixed Area | ||

| + | |||

| + | Berikut merupakan hasil perhitungan dengan fixed area | ||

| + | |||

| + | Dan berikut merupakan grafik yang diperoleh dengan menggunakan metode Curve Fitting | ||

| + | |||

| + | [[File:Tubes Metnum Faizal Rikaz A_4 Fixed Area.jpg|800px]] | ||

| + | |||

| + | [[File:Tubes Metnum Faizal Rikaz A_6 Fixed Area.jpg|300px]] | ||

| + | |||

| + | Dari hasil diatas dapat dilihat bahwa hasil yang paling optimum adalah SS316 dengan dimensi 30x30x3mm | ||

| + | |||

| + | |||

| + | ===Ujian Akhir Semester/ UAS (13/01/21)=== | ||

| + | Pada pertemuan kali ini diadakan Ujian Akhir Semester yang diadakan secara Daring/ Online. Berikut merupakan hasil pekerjaan/ jawaban dari UAS Metode Numerik saya. | ||

| + | |||

| + | '''Jawaban UAS No. 1''' | ||

| + | |||

| + | [[File:UAS_METNUM_Faizal Rikaz A_No. 1.jpg|500px|center]] | ||

| + | |||

| + | '''Jawaban UAS No. 2 & 3''' | ||

| + | |||

| + | [[File:UAS_METNUM_Faizal Rikaz A_No. 2 & 3.jpg|500px|center]] | ||

| + | |||

| + | '''Jawaban UAS No. 4 & 5''' | ||

| + | |||

| + | [[File:UAS_METNUM_Faizal Rikaz A_No. 4 & 5.jpg|500px|center]] | ||

| + | |||

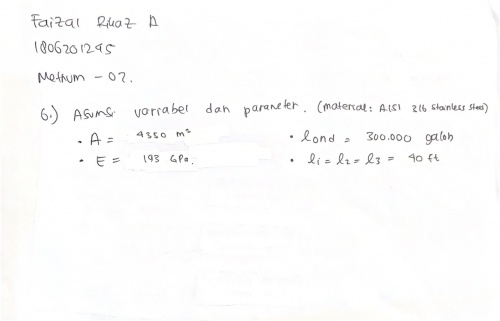

| + | '''Jawaban UAS No. 6''' | ||

| + | |||

| + | [[File:UAS_METNUM_Faizal Rikaz A_No. 6.jpg|500px|center]] | ||

| + | |||

| + | '''Jawaban UAS No. 7''' | ||

| + | |||

| + | Berikut merupakan code untuk menjawab soal no. 7 | ||

| + | |||

| + | model Metnum02_UAS_Faizal_Rikaz | ||

| + | //define initial variable | ||

| + | parameter Integer Points = size(P, 1); | ||

| + | //Number of Points | ||

| + | parameter Integer Trusses = size(C, 1); | ||

| + | //Number of Trusses | ||

| + | parameter Real Yield = 290e6; | ||

| + | //Yield Strength (Pa) | ||

| + | parameter Real Area = 4350; | ||

| + | //Area L Profile | ||

| + | parameter Real Elas = 193e9; | ||

| + | //Elasticity Stainless Steel 201 (Pa) | ||

| + | //define connection | ||

| + | parameter Integer C[:, 2] = [1, 2; 1, 3; 1, 4]; | ||

| + | //define coordinates (please put orderly) | ||

| + | parameter Real P[:, 6] = [0, 0, 0, 1, 1, 1; //1 | ||

| + | 6.5, 6.5, 36.5, 1, 1, 1; //2 | ||

| + | 6.5, 6.5, 36.5, 1, 1, 1; //3 | ||

| + | 6.5, 6.5, 36.5, 1, 1, 1]; //4 | ||

| + | //define external force (please put orderly) | ||

| + | parameter Real F[Points * 3] = {0,0,0,0,3708180,0,0,3708180,0,0,3708180,0}; | ||

| + | //solution | ||

| + | Real displacement[N], reaction[N]; | ||

| + | Real check[3]; | ||

| + | Real stress1[Trusses]; | ||

| + | Real safety[Trusses]; | ||

| + | Real dis[3]; | ||

| + | Real Str[3]; | ||

| + | protected | ||

| + | parameter Integer N = 3 * Points; | ||

| + | Real q1[3], q2[3], g[N, N], G[N, N], G_star[N, N], id[N, N] = identity(N), cx, cy, cz, L, X[3, 3]; | ||

| + | Real err = 10e-10, ers = 10e-4; | ||

| + | algorithm | ||

| + | //Creating Global Matrix | ||

| + | G := id; | ||

| + | for i in 1:Trusses loop | ||

| + | for j in 1:3 loop | ||

| + | q1[j] := P[C[i, 1], j]; | ||

| + | q2[j] := P[C[i, 2], j]; | ||

| + | end for; | ||

| + | L := Modelica.Math.Vectors.length(q2 - q1); | ||

| + | cx := (q2[1] - q1[1]) / L; | ||

| + | cy := (q2[2] - q1[2]) / L; | ||

| + | cz := (q2[3] - q1[3]) / L; | ||

| + | X := Area * Elas / L * [cx ^ 2, cx * cy, cx * cz; cy * cx, cy ^ 2, cy * cz; cz * cx, cz * cy, cz ^ 2]; | ||

| + | g := zeros(N, N); | ||

| + | for m, n in 1:3 loop | ||

| + | g[3 * (C[i, 1] - 1) + m, 3 * (C[i, 1] - 1) + n] := X[m, n]; | ||

| + | g[3 * (C[i, 2] - 1) + m, 3 * (C[i, 2] - 1) + n] := X[m, n]; | ||

| + | g[3 * (C[i, 2] - 1) + m, 3 * (C[i, 1] - 1) + n] := -X[m, n]; | ||

| + | g[3 * (C[i, 1] - 1) + m, 3 * (C[i, 2] - 1) + n] := -X[m, n]; | ||

| + | end for; | ||

| + | G_star := G + g; | ||

| + | G := G_star; | ||

| + | end for; | ||

| + | //Solving Matrix | ||

| + | //Transforming to global matrix | ||

| + | //Implementing boundary | ||

| + | for x in 1:Points loop | ||

| + | if P[x, 4] <> 0 then | ||

| + | for a in 1:Points * 3 loop | ||

| + | G[x * 3 - 2, a] := 0; | ||

| + | G[x * 3 - 2, x * 3 - 2] := 1; | ||

| + | end for; | ||

| + | end if; | ||

| + | if P[x, 5] <> 0 then | ||

| + | for a in 1:Points * 3 loop | ||

| + | G[x * 3 - 1, a] := 0; | ||

| + | G[x * 3 - 1, x * 3 - 1] := 1; | ||

| + | end for; | ||

| + | end if; | ||

| + | if P[x, 6] <> 0 then | ||

| + | for a in 1:Points * 3 loop | ||

| + | G[x * 3, a] := 0; | ||

| + | G[x * 3, x * 3] := 1; | ||

| + | end for; | ||

| + | end if; | ||

| + | end for; | ||

| + | //Solving displacement | ||

| + | displacement := Modelica.Math.Matrices.solve(G, F); | ||

| + | //Solving reaction | ||

| + | reaction := G_star * displacement - F; | ||

| + | //Eliminating float error | ||

| + | for i in 1:N loop | ||

| + | reaction[i] := if abs(reaction[i]) <= err then 0 else reaction[i]; | ||

| + | displacement[i] := if abs(displacement[i]) <= err then 0 else displacement[i]; | ||

| + | end for; | ||

| + | //Checking Force | ||

| + | check[1] := sum({reaction[i] for i in 1:3:N - 2}) + sum({F[i] for i in 1:3:N - 2}); | ||

| + | check[2] := sum({reaction[i] for i in 2:3:N - 1}) + sum({F[i] for i in 2:3:N - 1}); | ||

| + | check[3] := sum({reaction[i] for i in 3:3:N}) + sum({F[i] for i in 3:3:N}); | ||

| + | for i in 1:3 loop | ||

| + | check[i] := if abs(check[i]) <= ers then 0 else check[i]; | ||

| + | end for; | ||

| + | //Calculating stress in each truss | ||

| + | for i in 1:Trusses loop | ||

| + | for j in 1:3 loop | ||

| + | q1[j] := P[C[i, 1], j]; | ||

| + | q2[j] := P[C[i, 2], j]; | ||

| + | dis[j] := abs(displacement[3 * (C[i, 1] - 1) + j] - displacement[3 * (C[i, 2] - 1) + j]); | ||

| + | end for; | ||

| + | L := Modelica.Math.Vectors.length(q2 - q1); | ||

| + | cx := (q2[1] - q1[1]) / L; | ||

| + | cy := (q2[2] - q1[2]) / L; | ||

| + | cz := (q2[3] - q1[3]) / L; | ||

| + | X := Elas / L * [cx ^ 2, cx * cy, cx * cz; cy * cx, cy ^ 2, cy * cz; cz * cx, cz * cy, cz ^ 2]; | ||

| + | Str := X * dis; | ||

| + | stress1[i] := Modelica.Math.Vectors.length(Str); | ||

| + | end for; | ||

| + | //Solving Matrix | ||

| + | //Safety factor | ||

| + | for i in 1:Trusses loop | ||

| + | if stress1[i] > 0 then | ||

| + | safety[i] := Yield / stress1[i]; | ||

| + | else | ||

| + | safety[i] := 0; | ||

| + | end if; | ||

| + | end for; | ||

| + | |||

| + | end Metnum02_UAS_Faizal_Rikaz; | ||

| + | |||

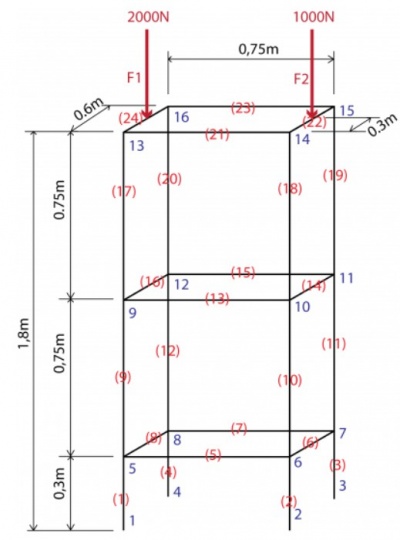

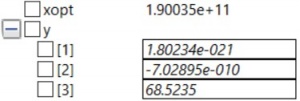

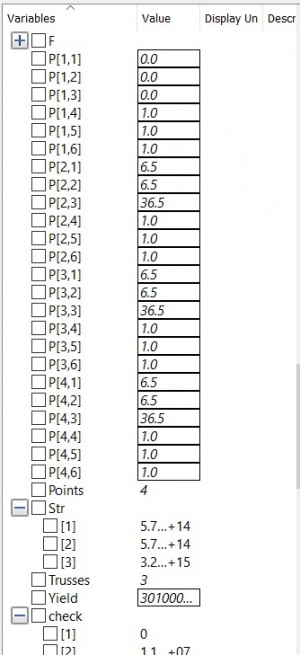

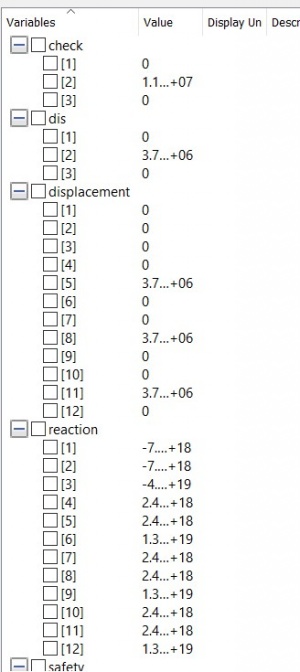

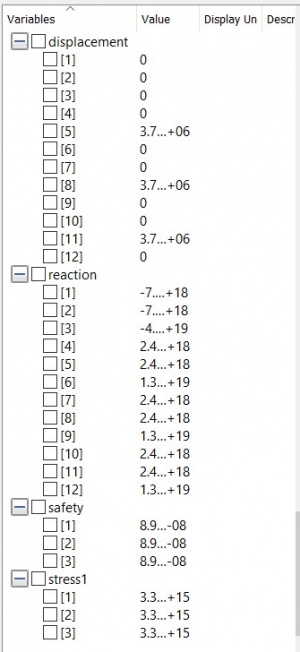

| + | Berikut merupakan hasil coding yang telah disimulasikan pada aplikasi OpenModelica | ||

| + | |||

| + | [[File:Hasil Coding 1.jpg|750px|center]] | ||

| + | |||

| + | [[File:Hasil Coding 2.jpg|750px|center]] | ||

| + | |||

| + | [[File:Hasil Coding 3.jpg|750px|center]] | ||

| + | |||

| + | [[File:Hasil Coding 4.jpg|750px|center]] | ||

| + | |||

| + | Berikut merupakan hasil dari simulasi pada aplikasi OpenModelica | ||

| + | |||

| + | [[File:Hasil_Simulasi_1.jpg|300px|center]] [[File:Hasil Simulasi 2.jpg|300px|center]] | ||

| + | |||

| + | [[File:Hasil Simulasi 3.jpg|300px|center]] [[File:Hasil Simulasi 4.jpg|300px|center]] | ||

| + | |||

| + | [[File:Hasil Simulasi 5.jpg|300px|center]] [[File:Hasil Simulasi 6.jpg|300px|center]] | ||

Latest revision as of 23:00, 14 January 2021

Selamat Datang di laman Wiki saya!

Biodata

Nama : Faizal Rikaz Al Muntaqo

NPM : 1806201245

TTL : Jakarta, 15 Desember 1999

Hobi : Futsal

Saya adalah seorang mahasiswa Teknik Mesin UI angkatan 2018. Ketertarikan saya kepada Jurusan Teknik Mesin salah satunya didasari oleh rasa penasaran dan kesukaan saya terhadap teknologi yang terus berkembang tiap harinya dan dan juga tidak sedikit saya mendapatkan pengaruh secara tidak langsung dari ayah saya yang juga merupakan seorang Engineer. Saya sangat berharap nantinya ilmu ilmu yang telah saya dapatkan dari perkuliahan dapat diaplikasikan dikehidupan saya kedepannya dan semoga dapat berguna bagi keluarga, agama dan bangsa Indonesia.

Contents

Metode Numerik

Tujuan Pembelajaran

Tujuan pembelajaran dari mata kuliah Metode Numerik ini adalah:

- 1.Memahami konsep dan prinsip dasar dalam metode numerik (contoh:Persamaan aljabar, algorithma, dll)

- 2. Mengerti dan dapat mengaplikasikan aplikasi metode numerik

- 3. Mampu menerapkan ilmu-ilmu metode numerik dalam persoalan teknik

- 4. Mendapat nilai tambah adab sehingga dapat menjadi orang yang lebih beradab

Review Materi(Sebelum UTS)

Beberapa topik yang dibahas pada saat sebelum UTS meliputi:

- 1. Deret Taylor dan McLaurin

- 2. Regresi Linear

- 3. Interpolasi

- 4. Pseudocode

Pertemuan 1 (11/11/20)

Tugas Pertemuan 1 adalah mempelajari Modelica melalui situs Youtube lalu membuat video pembelajaran tentang Modelica kemudian di-upload di channel Youtube. Saya mempelajari Modelica melalui youtube pada situs berikut:

https://www.youtube.com/watch?v=m0Ahs8fEN28

Dan berikut merupakan Tugas video pembelajaran saya pada aplikasi modelica.

Pertemuan 2 (18/11/20)

Pada pertemuan kali ini kami sharing tugas yang telah diberikan diminggu lalu. Perbedaan Modelica dan Bahasa Coding lainnya (seperti: Phyton, dll) adalah modelica merupakan bahasa permodelan dan berbeda dengan bahasa coding sperti phyton dll. Pada proses simulate Open Modellica cukup lama karena proses dari bahasa modelica ke C lalu baru ke bahasa mesin. Namun ketika kita hanya merubah parameternya saja dengan cara me-resimulate maka proses akan cepat, karena tidak melewati proses perubahan bahasa lagi.

Mengapa menggunakan open modelica?

- - Cocok dengan engineer

- - Sistem perhitungan cepat

- - Banyak penggunanya

- - Free/ open technology

Tugas Video: https://www.youtube.com/watch?v=nVaCw_QBNaY

Pertemuan 3 (25/11/20)

Pada pertemuan ke 3 ini mempelajari tentang pseoudocode gauss elemination, lalu Pseudocode gauss dijelaskan oleh teman sekelas kami yaitu Christo. Lalu kami juga ditugaskan untuk membuat program sederhana menggunakan Open Modelica untuk menyelesaikan sebuah permasalahan yaitu mengenai Truss. Berikut Tugas Truss yang telah saya kerjakan.

TUGAS TRUSSES

class Tugas_Trusses parameter Integer N=8; //Global Matrice parameter Real A=0.001; //Area m2 parameter Real E=200e9; //Pa Real KG[N,N]; //global Real KGinitial[N,N]; //global Real Sol[N]; //global dispplacement Real X[N]={0,0,-1035.2762,-3863.7033,0,0,-1035.2762,-3863.7033}; Real R[N]; Real SolMat[N,1]; Real XMat[N,1]; Real L1=1; Real L2=1; Real L3=1.6; Real L4=1.25; Real L5=1.6; Real Tetha1=degtorad(0); Real Tetha2=degtorad(0); Real Tetha3=degtorad(231.34); Real Tetha4=degtorad(270); Real Tetha5=degtorad(308.66); //Boundary condition Integer b1=1; Integer b2=3; //Truss 1 Real X1=Tetha1; Real k1=A*E/L1; Real K1[4,4]; //stiffness matrice Real KG1[N,N]; Integer p1o=1; Integer p1i=2; //Truss 2 Real X2=Tetha2; Real k2=A*E/L2; Real K2[4,4]; //stiffness matrice Real KG2[N,N]; Integer p2o=2; Integer p2i=3; //Truss 3 Real X3=Tetha1; Real k3=A*E/L3; Real K3[4,4]; //stiffness matrice Real KG3[N,N]; Integer p3o=2; Integer p3i=4; //Truss 4 Real X4=Tetha4; Real k4=A*E/L4; Real K4[4,4]; //stiffness matrice Real KG4[N,N]; Integer p4o=1; Integer p4i=4; //Truss 5 Real X5=Tetha5; Real k5=A*E/L5; Real K5[4,4]; //stiffness matrice Real KG5[N,N]; Integer p5o=3; Integer p5i=4; algorithm //Pembuatan Matrice Global K1:=Stiffness_Matrices(X1); KG1:=k1*Local_Global(K1,N,p1o,p1i); K2:=Stiffness_Matrices(X2); KG2:=k2*Local_Global(K2,N,p2o,p2i); K3:=Stiffness_Matrices(X3); KG3:=k3*Local_Global(K3,N,p3o,p3i); K4:=Stiffness_Matrices(X4); KG4:=k4*Local_Global(K4,N,p4o,p4i); K5:=Stiffness_Matrices(X5); KG5:=k5*Local_Global(K5,N,p5o,p5i); KG:=KG1+KG2+KG3+KG4+KG5; KGinitial:=KG; //Implementing Boundary Condition for i in 1:N loop KG[2*b1-1,i]:=0; KG[2*b1,i]:=0; KG[2*b2-1,i]:=0; KG[2*b2,i]:=0; end for; KG[2*b1-1,2*b1-1]:=1; KG[2*b1,2*b1]:=1; KG[2*b2-1,2*b2-1]:=1; KG[2*b2,2*b2]:=1; //Solving Displacement Sol:=Gauss_Jordan(N,KG,X); //Solving Reaction Force SolMat:=matrix(Sol); XMat:=matrix(X); R:=Reaction_Trusses(N,KGinitial,SolMat,XMat); end Tugas_Trusses;

Fungsi Degtorad

function Degtorad input Real deg; output Real rad; protected constant Real pi = 3.14; algorithm rad:=deg*pi/180; end Degtorad;

Fungsi Stiffness Matrices

function Stiffness_Matrices

input Real A;

output Real X[4,4];

protected

Real Y;

Real float_error = 10e-10;

final constant Real pi=2*Modelica.Math.asin(1.0);

algorithm

Y:=A/180*pi;

X:=[(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.cos(Y))^2,-

Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

Modelica.Math.cos(Y)*Modelica.Math.sin(Y),(Modelica.Math.sin(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-

(Modelica.Math.sin(Y))^2;

-(Modelica.Math.cos(Y))^2,-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),

(Modelica.Math.cos(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y);

-Modelica.Math.cos(Y)*Modelica.Math.sin(Y),-(Modelica.Math.sin(Y))^2,Modelica.Math.cos(Y)*Modelica.Math.sin(Y),

(Modelica.Math.sin(Y))^2];

for i in 1:4 loop

for j in 1:4 loop

if abs(X[i,j]) <= float_error then

X[i,j] := 0;

end if;

end for;

end for;

end Stiffness_Matrices;

Fungsi Local Global

function Local_Global input Real Y[4,4]; input Integer B; input Integer p1; input Integer p2; output Real G[B,B]; algorithm for i in 1:B loop for j in 1:B loop G[i,j]:=0; end for; end for; G[2*p1,2*p1]:=Y[2,2]; G[2*p1-1,2*p1-1]:=Y[1,1]; G[2*p1,2*p1-1]:=Y[2,1]; G[2*p1-1,2*p1]:=Y[1,2]; G[2*p2,2*p2]:=Y[4,4]; G[2*p2-1,2*p2-1]:=Y[3,3]; G[2*p2,2*p2-1]:=Y[4,3]; G[2*p2-1,2*p2]:=Y[3,4]; G[2*p2,2*p1]:=Y[4,2]; G[2*p2-1,2*p1-1]:=Y[3,1]; G[2*p2,2*p1-1]:=Y[4,1]; G[2*p2-1,2*p1]:=Y[3,2]; G[2*p1,2*p2]:=Y[2,4]; G[2*p1-1,2*p2-1]:=Y[1,3]; G[2*p1,2*p2-1]:=Y[2,3]; G[2*p1-1,2*p2]:=Y[1,4]; end Local_Global;

Fungsi Reaction Trusses

function Reaction_Trusses input Integer N; input Real A[N,N]; input Real B[N,1]; input Real C[N,1]; output Real Sol[N]; protected Real X[N,1]; Real float_error = 10e-10; algorithm X:=A*B-C; for i in 1:N loop if abs(X[i,1]) <= float_error then X[i,1] := 0; end if; end for; for i in 1:N loop Sol[i]:=X[i,1]; end for; end Reaction_Trusses;

TUGAS GAUSS JORDAN

function Tugas_GaussJordan

input Real [:,:] A;

output Real [:,:] B;

protected // local variable

Integer h = 1; //pivot row

Integer k = 1; //pivot coloumn

Integer m = size(A,1); //Number of row

Integer n = size(A,2); //Number of column

Integer c = 0;

Integer max_row; // Row index of max number in pivot column

Real [:] pivot_column;

Real [:] pivot_row;

Real [:,:] temp_array;

Real r;

Real float_error = 10e-10;

algorithm

//function input A and output B

B := A;

while h <= m and k <= n loop

for i in 1 : m loop

for j in 1 : n loop

if abs(B[i,j]) <= float_error then

B[i,j] := 0;

end if;

end for;

end for;

//Finding pivot

pivot_column:= {B[i,h] for i in h:m};

//Search for the bottom row that has the highest pivot value

c:=h-1;

for element in pivot_column loop

c:= c+1;

if abs(element)== max(abs(pivot_column)) then

max_row :=c;

end if;

end for;

//If there are no pivots in this column, move to the next column

if B[max_row,k] == 0 then

k:=k+1;

else

// switch row h - max_row

temp_array := B;

temp_array[h] := B[max_row];

temp_array[max_row] := B[h];

B:= temp_array;

//devide pivot row by pivot number

B[h] := B[h]/B[h,k];

for i in (h+1) :m loop

r := B[i,k]/B[h,k];

B[i,k]:=0;

for j in (k+1) : n loop

B[i,j] := B[i,j]-B[h,j] * r;

end for;

end for;

//move to pivot column and the next row

h := h+1;

k := k+1;

end if;

end while;

// from the top right

h :=m;

k :=n;

while h >=1 and k>=1 loop

//dealing with error

for i in 1:m loop

for j in 1:n loop

if abs(B[i,j]) <=float_error then

B[i,j]:=0;

end if;

end for;

end for;

//finding pivot

pivot_row := {B[h,i] for i in 1:k};

//Get position index k of pivot

c := 0;

for element in pivot_row loop

c := c+1;

if element <> 0 then

break;

end if;

end for;

k:= c;

// no pivot in this row, move to next row

if B[h,k] == 0 then

h:= h-1;

else

//perform row operatation

for i in 1:(h-1) loop

r := B[i,k];

B[i] := B[i] - B[h] *r;

end for;

//move to next pivot row dan column

h:=h+1;

k:=k+1;

end if;

end while;

end Tugas_GaussJordan;

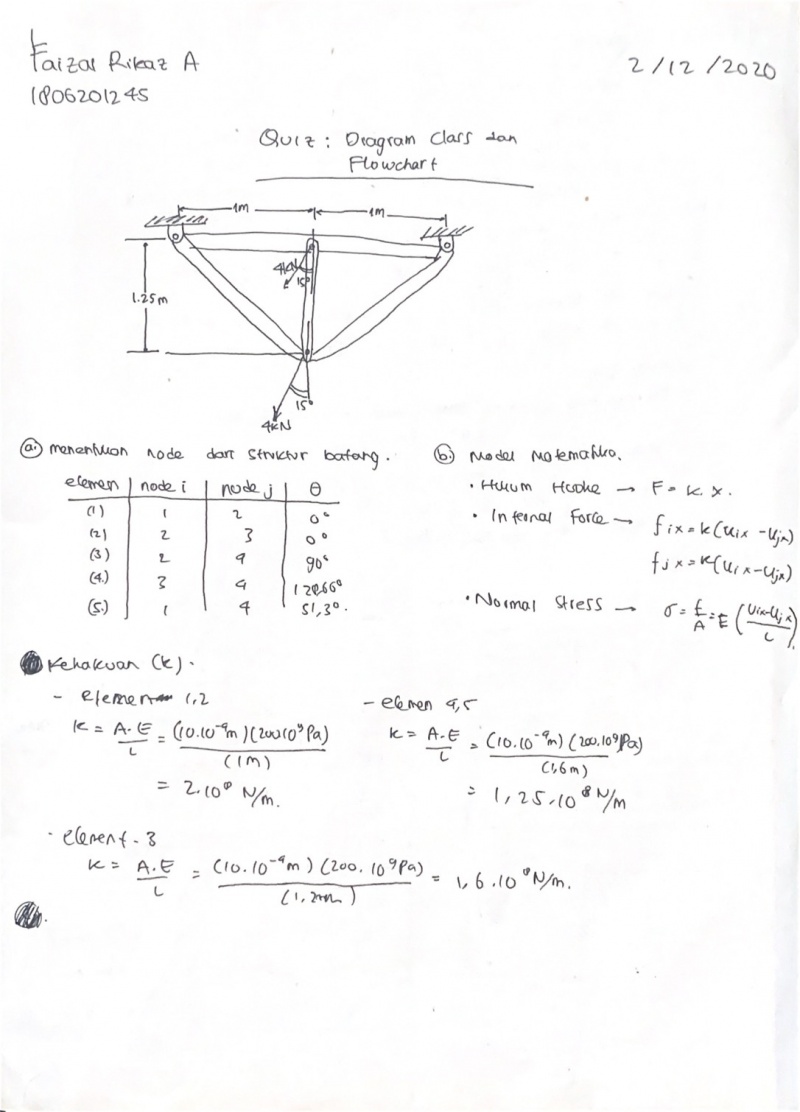

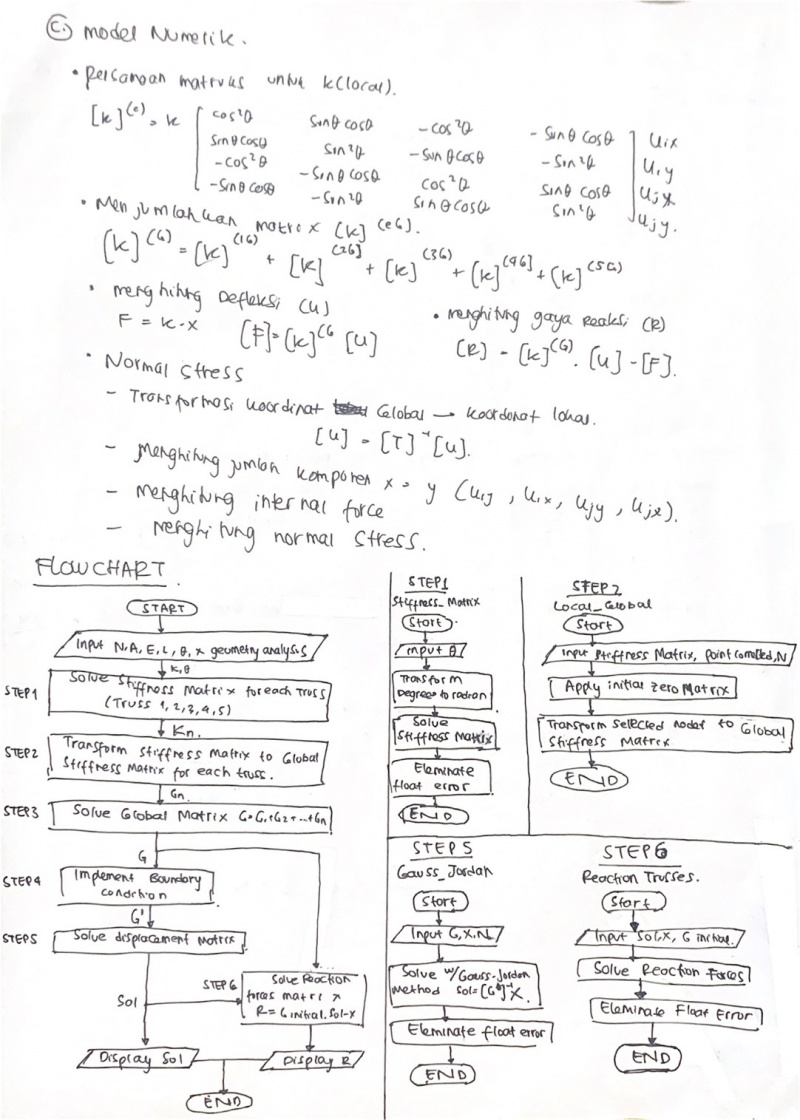

Pertemuan 4 (02/12/20)

Membuat diagram class dan flowchart

QUIZ 1

Berikut jawaban beserta Flowchart dari QUIZ 1 saya.

TUGAS PERTEMUAN 4

Berikut merupakan jawaban dari Tugas Pertemuan 4 saya

Pertemuan 5 (16/12/20)

Pertemuan kali ini kami belajar melalui video yang diberikan Bu Chandra tentang aplikasi metode numerik dalam optimasi sebuah sistem menggunakan OpenModelica. Dibahas pula contoh dari optimasi menggunakan metode Bracket. Berikut pseudocode yang digunakan pada OpenModelica :

FungsiObjek.mo function FungsiObjek input Real x; output Real y; algorithm y:= 2*Modelica.Math.sin(x)-x^2/10; end FungsiObjek;

Fungsi panggil

BracketOptimal.mo

model BracketOptimal

parameter Integer n = 8;

Real x1[n];

Real x2[n];

Real xup;

Real xlow;

Real f1[n];

Real f2[n];

Real xopt;

Real yopt;

Real d;

algorithm

xup := 4;

xlow := 0;

for i in 1:n loop

d:=((5^(1/2)-1)/2) * (xup-xlow);

x1[i] := xlow+d;

x2[i] := xup-d;

f1[i] := FungsiObjek(x1[i]);

f2[i] := FungsiObjek(x2[i]);

if f1[i]>f2[i] then

xup := xup;

xlow := x2[i];

xopt := xup;

yopt := f1[i];

else

xlow :=xlow;

xup := x1[i];

xopt := xup;

end if;

end for;

end BracketOptimal;

Pertemuan 6 (23/12/20)

TUGAS BESAR

Pada pertemuan ke 6 ini kami diberi sebuah tugas besar yang dimana mahasiswa diharuskan mendesign suatu rangka dengan hasil yang terbaik namun juga memerhatikan cost agar mndapat harga yang relatif murah pula. Selain mempertimbangkan biaya serta material, area cross section truss pun juga ikut dipertimbangkan.

Pendefinisian

Berikut merupakan pendefinisian node dan elemen pada struktur batang.

Asumsi dan Constraint pada problem

Asumsi

*Material *Luas permukaan truss *Tidak adanya bending *Beban terdistribusi di node - node *Batas displacement 0,001m sebelum buckling *Nilai safety factor 2

Constraint:

*Node 1, 2, 3, dan 4 fixed. *Beban F1 dan F2 terdistribusi ke node sekitarnya *Node 13 & 16 = 1000N *Node 14 & 15 = 500N

Data yang digunakan

Berikut merupakan dua metode pendekatan yang digunakan dalam pencarian dimensi area dan material teroptimal dalam pembentukan rangka.

Permodelan Numerik

Berikut merupakan permodelan numerik dan komputasi pada Open Modelica

//define initial variable

parameter Integer Points=size(P,1); //Number of Points

parameter Integer Trusses=size(C,1); //Number of Trusses

parameter Real Yield=2.0e8; //Yield Strength (Pa)

parameter Real Area=0.0001727; //Area L Profile (Dimension=0.03, Thickness=0,004) (m2)

parameter Real Elas=192e11; //Elasticity SS 316 (Pa)

model TugasBesar_FaizalRikaz

//define connection

parameter Integer C[:,2]=[1,5;

2,6;

3,7;

4,8;

5,6; //1st floor

6,7; //1st floor

7,8; //1st floor

5,8; //1st floor

5,9;

6,10;

7,11;

8,12;

9,10; //2nd floor

10,11;//2nd floor

11,12;//2nd floor

9,12; //2nd floor

9,13;

10,14;

11,15;

12,16;

13,14;//3rd floor

14,15;//3rd floor

15,16;//3rd floor

13,16];//3rd floor

//define coordinates (please put orderly)

parameter Real P[:,6]=[0.3,-0.375,0,1,1,1; //1

-0.3,-0.375,0,1,1,1; //2

-0.3,0.375,0,1,1,1; //3

0.3,0.375,0,1,1,1; //4

0.3,-0.375,0.6,0,0,0; //5

-0.3,-0.375,0.6,0,0,0; //6

-0.3,0.375,0.6,0,0,0; //7

0.3,0.375,0.6,0,0,0; //8

0.3,-0.375,1.2,0,0,0; //9

-0.3,-0.375,1.2,0,0,0; //10

-0.3,0.375,1.2,0,0,0; //11

0.3,0.375,1.2,0,0,0; //12

0.3,-0.375,1.8,0,0,0; //13

-0.3,-0.375,1.8,0,0,0; //14

-0.3,0.375,1.8,0,0,0; //15

0.3,0.375,1.8,0,0,0]; //16

//define external force (please put orderly)

parameter Real F[Points*3]={0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,0,

0,0,-500,

0,0,-1000,

0,0,-1000,

0,0,-500};

//solution

Real displacement[N], reaction[N];

Real check[3];

Real stress1[Trusses];

Real safety[Trusses];

Real dis[3];

Real Str[3];

protected

parameter Integer N=3*Points;

Real q1[3], q2[3], g[N,N], G[N,N], G_star[N,N], id[N,N]=identity(N), cx, cy, cz, L, X[3,3];

Real err=10e-10, ers=10e-4;

algorithm

//Creating Global Matrix

G:=id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Area*Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

//Transforming to global matrix

g:=zeros(N,N);

for m,n in 1:3 loop

g[3*(C[i,1]-1)+m,3*(C[i,1]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,2]-1)+n]:=X[m,n];

g[3*(C[i,2]-1)+m,3*(C[i,1]-1)+n]:=-X[m,n];

g[3*(C[i,1]-1)+m,3*(C[i,2]-1)+n]:=-X[m,n];

end for;

G_star:=G+g;

G:=G_star;

end for;

//Implementing boundary

for x in 1:Points loop

if P[x,4] <> 0 then

for a in 1:Points*3 loop

G[(x*3)-2,a]:=0;

G[(x*3)-2,(x*3)-2]:=1;

end for;

end if;

if P[x,5] <> 0 then

for a in 1:Points*3 loop

G[(x*3)-1,a]:=0;

G[(x*3)-1,(x*3)-1]:=1;

end for;

end if;

if P[x,6] <> 0 then

for a in 1:Points*3 loop

G[x*3,a]:=0;

G[x*3,x*3]:=1;

end for;

end if;

end for;

//Solving displacement

displacement:=Modelica.Math.Matrices.solve(G,F);

//Solving reaction

reaction:=(G_star*displacement)-F;

//Eliminating float error

for i in 1:N loop

reaction[i]:=if abs(reaction[i])<=err then 0 else reaction[i];

displacement[i]:=if abs(displacement[i])<=err then 0 else displacement[i];

end for;

//Checking Force

check[1]:=sum({reaction[i] for i in (1:3:(N-2))})+sum({F[i] for i in (1:3:(N-2))});

check[2]:=sum({reaction[i] for i in (2:3:(N-1))})+sum({F[i] for i in (2:3:(N-1))});

check[3]:=sum({reaction[i] for i in (3:3:N)})+sum({F[i] for i in (3:3:N)});

for i in 1:3 loop

check[i] := if abs(check[i])<=ers then 0 else check[i];

end for;

//Calculating stress in each truss

for i in 1:Trusses loop

for j in 1:3 loop

q1[j]:=P[C[i,1],j];

q2[j]:=P[C[i,2],j];

dis[j]:=abs(displacement[3*(C[i,1]-1)+j]-displacement[3*(C[i,2]-1)+j]);

end for;

//Solving Matrix

L:=Modelica.Math.Vectors.length(q2-q1);

cx:=(q2[1]-q1[1])/L;

cy:=(q2[2]-q1[2])/L;

cz:=(q2[3]-q1[3])/L;

X:=(Elas/L)*[cx^2,cx*cy,cx*cz;

cy*cx,cy^2,cy*cz;

cz*cx,cz*cy,cz^2];

Str:=(X*dis);

stress1[i]:=Modelica.Math.Vectors.length(Str);

end for;

//Safety factor

for i in 1:Trusses loop

if stress1[i]>0 then

safety[i]:=Yield/stress1[i];

else

safety[i]:=0;

end if;

end for;

end TugasBesar_FaizalRikaz;

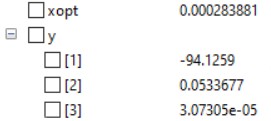

Kurva Curve Fitting

function Curve_Fitting input Real X[:]; input Real Y[size(X,1)]; input Integer order=2; output Real Coe[order+1]; protected Real Z[size(X,1),order+1]; Real ZTr[order+1,size(X,1)]; Real A[order+1,order+1]; Real B[order+1]; algorithm for i in 1:size(X,1) loop for j in 1:(order+1) loop Z[i,j]:=X[i]^(order+1-j); end for; end for; ZTr:=transpose(Z); A:=ZTr*Z; B:=ZTr*Y; Coe:=Modelica.Math.Matrices.solve(A,B); end Curve_Fitting;

Golden Section

model Opt_Gold

parameter Real xd[:];

parameter Real yd[size(xd,1)];

parameter Real xlo=87e-6;

parameter Real xhi=504e-6;

parameter Integer N=10; // maximum iteration

parameter Real es=0.0001; // maximum error

Real f1[N], f2[N], x1[N], x2[N], ea[N], y[3];

Real xopt, fx;

protected

Real d, xl, xu, xint, R=(5^(1/2)-1)/2;

algorithm

xl := xlo;

xu := xhi;

y := Curve_Fitting(xd,yd);

for i in 1:N loop

d:= R*(xu-xl);

x1[i]:=xl+d;

x2[i]:=xu-d;

f1[i]:=y[1]*x1[i]^2+y[2]*x1[i]+y[3];

f2[i]:=y[1]*x2[i]^2+y[2]*x2[i]+y[3];

xint:=xu-xl;

if f1[i]>f2[i] then

xl:=x2[i];

xopt:=x1[i];

fx:=f1[i];

else

xu:=x1[i];

xopt:=x2[i];

fx:=f2[i];

end if;

ea[i]:=(1-R)*abs((xint)/xopt);

if ea[i]<es then

break;

end if;

end for;

end Opt_Gold;

Hasil Perhitungan

- Fixed Elasticity

Berikut merupakan hasil perhitungan dengan fixed elasticity

Dan berikut merupakan grafik yang diperoleh dengan menggunakan metode Curve Fitting

Dari hasil diatas dapat dilihat bahwa hasil yang paling optimum adalah SS316 dengan dimensi 30x30x3mm

- Fixed Area

Berikut merupakan hasil perhitungan dengan fixed area

Dan berikut merupakan grafik yang diperoleh dengan menggunakan metode Curve Fitting

Dari hasil diatas dapat dilihat bahwa hasil yang paling optimum adalah SS316 dengan dimensi 30x30x3mm

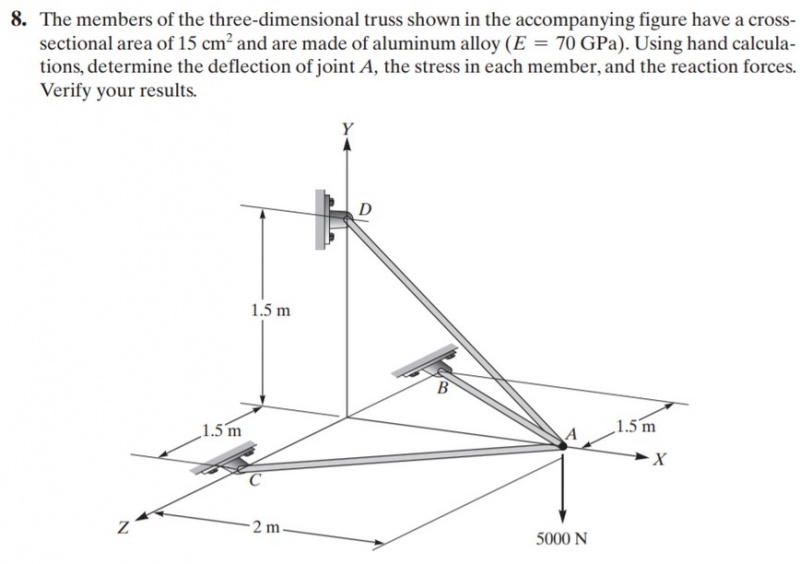

Ujian Akhir Semester/ UAS (13/01/21)

Pada pertemuan kali ini diadakan Ujian Akhir Semester yang diadakan secara Daring/ Online. Berikut merupakan hasil pekerjaan/ jawaban dari UAS Metode Numerik saya.

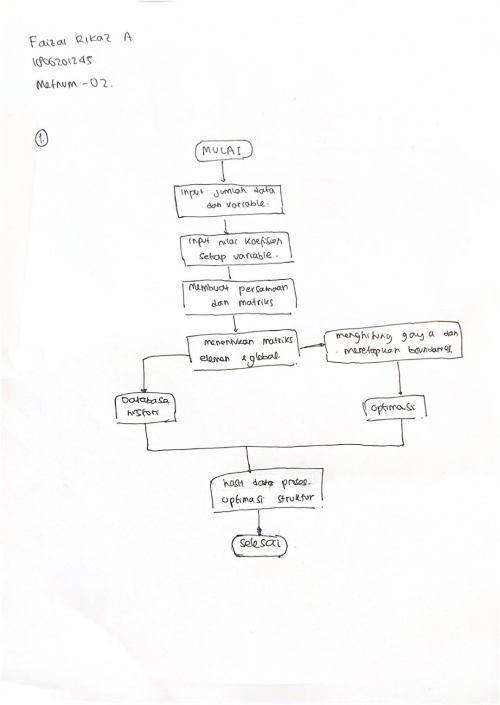

Jawaban UAS No. 1

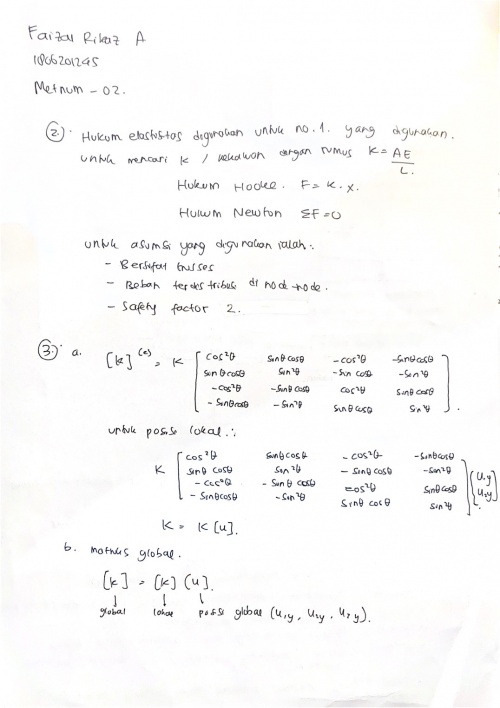

Jawaban UAS No. 2 & 3

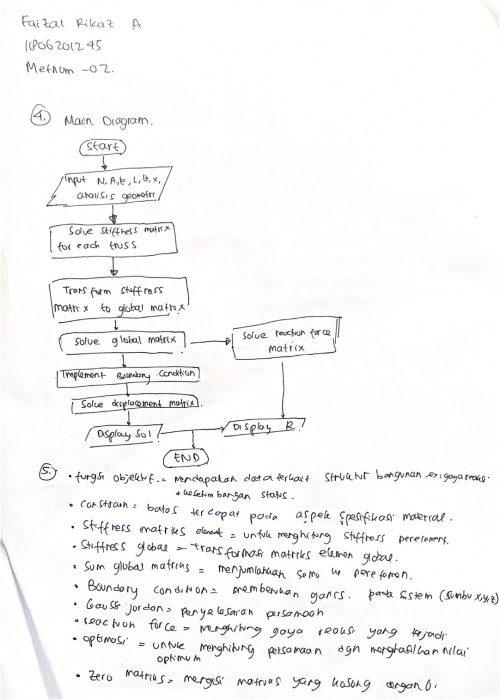

Jawaban UAS No. 4 & 5

Jawaban UAS No. 6

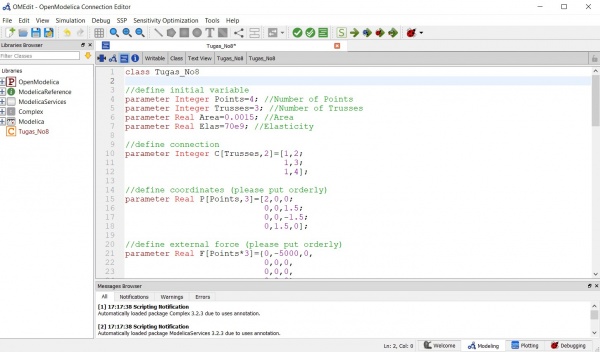

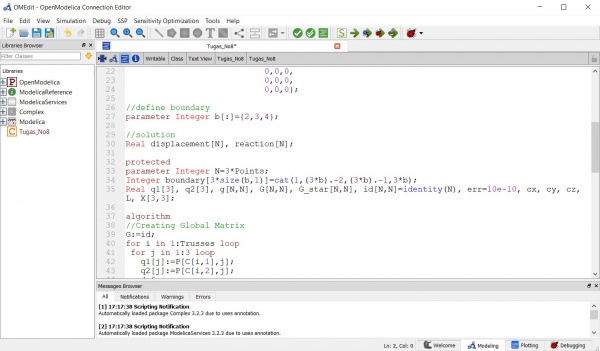

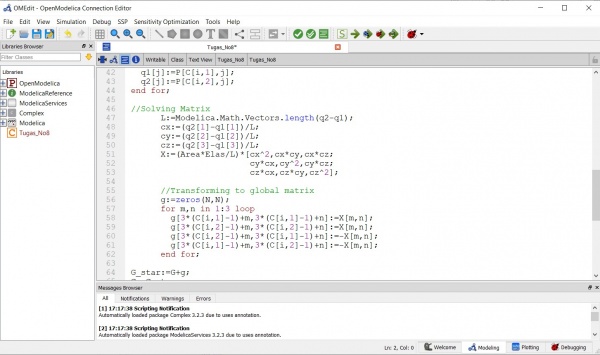

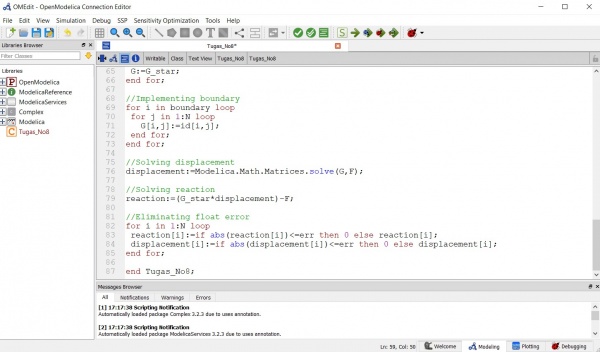

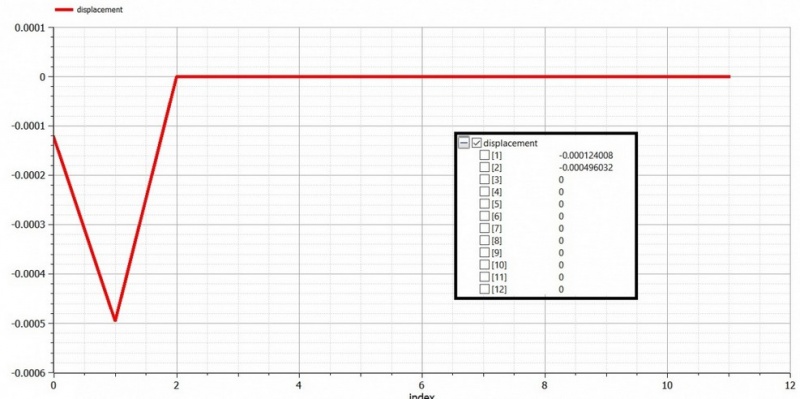

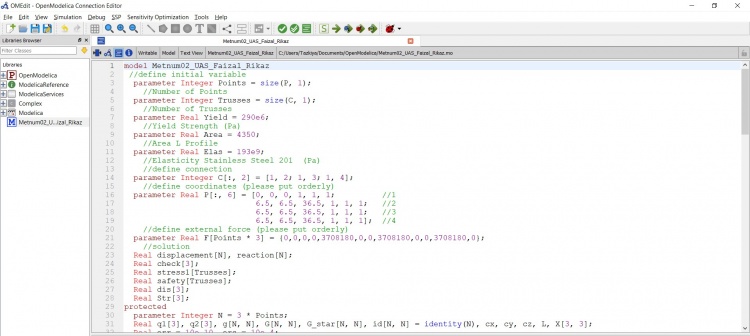

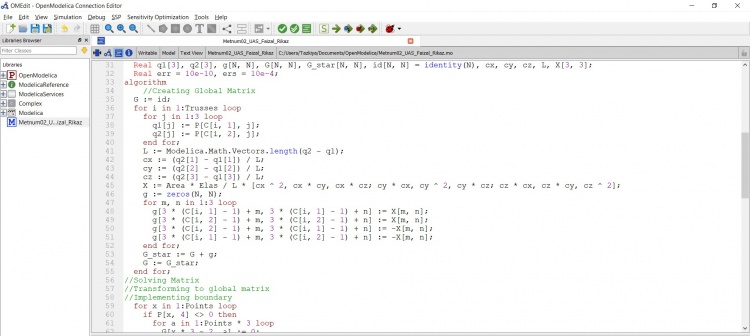

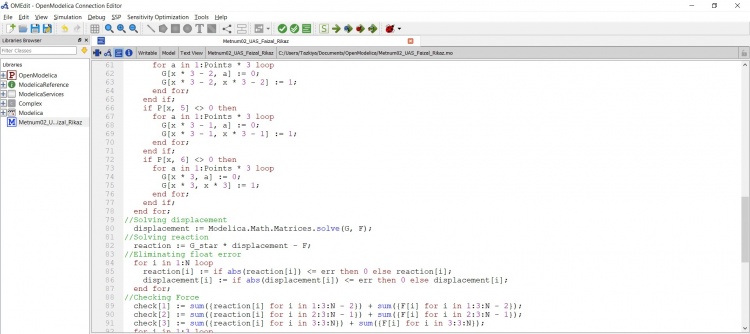

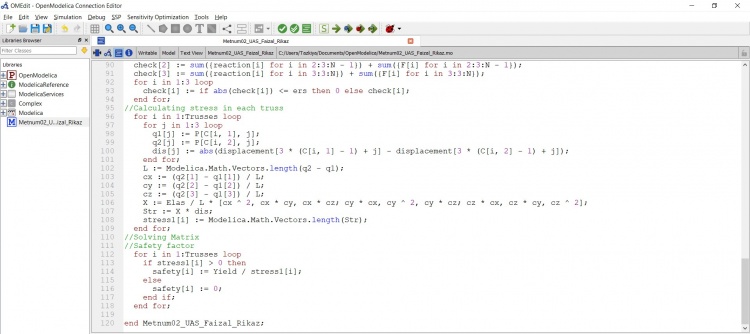

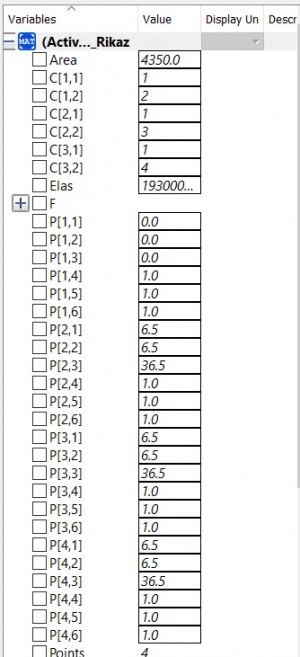

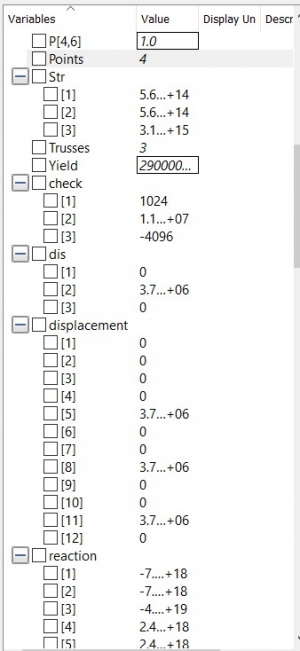

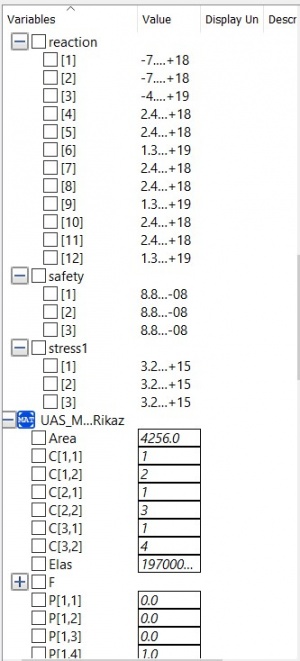

Jawaban UAS No. 7

Berikut merupakan code untuk menjawab soal no. 7

model Metnum02_UAS_Faizal_Rikaz

//define initial variable

parameter Integer Points = size(P, 1);

//Number of Points

parameter Integer Trusses = size(C, 1);

//Number of Trusses

parameter Real Yield = 290e6;

//Yield Strength (Pa)

parameter Real Area = 4350;

//Area L Profile

parameter Real Elas = 193e9;

//Elasticity Stainless Steel 201 (Pa)

//define connection

parameter Integer C[:, 2] = [1, 2; 1, 3; 1, 4];

//define coordinates (please put orderly)

parameter Real P[:, 6] = [0, 0, 0, 1, 1, 1; //1

6.5, 6.5, 36.5, 1, 1, 1; //2

6.5, 6.5, 36.5, 1, 1, 1; //3

6.5, 6.5, 36.5, 1, 1, 1]; //4

//define external force (please put orderly)

parameter Real F[Points * 3] = {0,0,0,0,3708180,0,0,3708180,0,0,3708180,0};

//solution

Real displacement[N], reaction[N];

Real check[3];

Real stress1[Trusses];

Real safety[Trusses];

Real dis[3];

Real Str[3];

protected

parameter Integer N = 3 * Points;

Real q1[3], q2[3], g[N, N], G[N, N], G_star[N, N], id[N, N] = identity(N), cx, cy, cz, L, X[3, 3];

Real err = 10e-10, ers = 10e-4;

algorithm

//Creating Global Matrix

G := id;

for i in 1:Trusses loop

for j in 1:3 loop

q1[j] := P[C[i, 1], j];

q2[j] := P[C[i, 2], j];

end for;

L := Modelica.Math.Vectors.length(q2 - q1);

cx := (q2[1] - q1[1]) / L;

cy := (q2[2] - q1[2]) / L;

cz := (q2[3] - q1[3]) / L;

X := Area * Elas / L * [cx ^ 2, cx * cy, cx * cz; cy * cx, cy ^ 2, cy * cz; cz * cx, cz * cy, cz ^ 2];

g := zeros(N, N);

for m, n in 1:3 loop

g[3 * (C[i, 1] - 1) + m, 3 * (C[i, 1] - 1) + n] := X[m, n];

g[3 * (C[i, 2] - 1) + m, 3 * (C[i, 2] - 1) + n] := X[m, n];

g[3 * (C[i, 2] - 1) + m, 3 * (C[i, 1] - 1) + n] := -X[m, n];

g[3 * (C[i, 1] - 1) + m, 3 * (C[i, 2] - 1) + n] := -X[m, n];

end for;

G_star := G + g;

G := G_star;

end for;

//Solving Matrix

//Transforming to global matrix

//Implementing boundary

for x in 1:Points loop

if P[x, 4] <> 0 then

for a in 1:Points * 3 loop

G[x * 3 - 2, a] := 0;

G[x * 3 - 2, x * 3 - 2] := 1;

end for;

end if;

if P[x, 5] <> 0 then

for a in 1:Points * 3 loop

G[x * 3 - 1, a] := 0;

G[x * 3 - 1, x * 3 - 1] := 1;

end for;

end if;

if P[x, 6] <> 0 then

for a in 1:Points * 3 loop

G[x * 3, a] := 0;

G[x * 3, x * 3] := 1;

end for;

end if;

end for;

//Solving displacement

displacement := Modelica.Math.Matrices.solve(G, F);

//Solving reaction

reaction := G_star * displacement - F;

//Eliminating float error

for i in 1:N loop

reaction[i] := if abs(reaction[i]) <= err then 0 else reaction[i];

displacement[i] := if abs(displacement[i]) <= err then 0 else displacement[i];

end for;

//Checking Force

check[1] := sum({reaction[i] for i in 1:3:N - 2}) + sum({F[i] for i in 1:3:N - 2});

check[2] := sum({reaction[i] for i in 2:3:N - 1}) + sum({F[i] for i in 2:3:N - 1});

check[3] := sum({reaction[i] for i in 3:3:N}) + sum({F[i] for i in 3:3:N});

for i in 1:3 loop

check[i] := if abs(check[i]) <= ers then 0 else check[i];

end for;

//Calculating stress in each truss

for i in 1:Trusses loop

for j in 1:3 loop

q1[j] := P[C[i, 1], j];

q2[j] := P[C[i, 2], j];

dis[j] := abs(displacement[3 * (C[i, 1] - 1) + j] - displacement[3 * (C[i, 2] - 1) + j]);

end for;

L := Modelica.Math.Vectors.length(q2 - q1);

cx := (q2[1] - q1[1]) / L;

cy := (q2[2] - q1[2]) / L;

cz := (q2[3] - q1[3]) / L;

X := Elas / L * [cx ^ 2, cx * cy, cx * cz; cy * cx, cy ^ 2, cy * cz; cz * cx, cz * cy, cz ^ 2];

Str := X * dis;

stress1[i] := Modelica.Math.Vectors.length(Str);

end for;

//Solving Matrix

//Safety factor

for i in 1:Trusses loop

if stress1[i] > 0 then

safety[i] := Yield / stress1[i];

else

safety[i] := 0;

end if;

end for;

end Metnum02_UAS_Faizal_Rikaz;

Berikut merupakan hasil coding yang telah disimulasikan pada aplikasi OpenModelica

Berikut merupakan hasil dari simulasi pada aplikasi OpenModelica